Sustainability is one of the most pressing issues that the global attractions industry faces. The combination of new legislation and visitor pressure means that becoming greener has moved from the realms of ‘nice to have’ to something that is essential. However, if the attractions industry is to make progress when it comes to environmental sustainability, everyone needs to do their part, from the theme park operators to the manufacturers and suppliers.

Intamin, a creator of record-breaking amusement rides, is one manufacturer that is reacting to this change. It is answering the call from operators to develop greener and more energy-efficient attractions.

To find out more about the firm’s innovations and discuss an example in action at one of Europe’s leading amusement parks, blooloop spoke to Patrick Spieldiener, president of Intamin, and Adrià Benito Pellicer, corporate sustainability engineer at Intamin.

A history of innovation

Thanks to its history of working at the cutting edge of attraction design, coming up with new innovations is nothing new for Intamin.

“We’re always being confronted with first-off world record attractions, so new innovative technologies are constantly being reviewed,” says Spieldiener. “Early on, things like power efficiency, wear/tear, use of resources and life expectancy are always high on the list of considerations. This is because such aspects are becoming exponentially more detrimental when pushing the envelope.”

In addition, green values were important to Intamin’s founders, and this ethos has stayed with the company. Robert Spieldiener, one of three men who co-founded Intamin Amusement Rides in 1967 established a philanthropic foundation called Stumme Brueder Stiftung. As well as supporting animal welfare and humanitarian projects, the foundation also finances projects in favour of environmental protection. .

The increasing demand for greener attractions

In recent years, Intamin has seen that clients are taking more interest in environmental sustainability. For ride manufacturers, learning about the impact of their attractions on the environment is a new topic. But it is also one that is increasingly being discussed. Keeping this issue in focus and working closely with its clients, Intamin is now working to analyse and mitigate this impact.

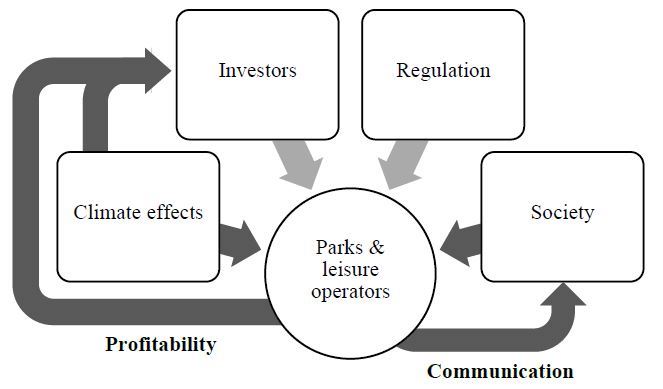

In 2022, Benito Pellicer discussed this trend with key players in the European industry. He identified four factors that are driving this increasing demand: (1) upcoming tighter governmental regulations, (2) access to investments linked to sustainability requirements, (3) increased awareness in society and their changes on consumption, and (4) the worsening of weather events and its impact on attendance and business.

“However, the industry is still lagging behind. We want to do our part and collaborate with parks in finding new alternative solutions and incremental improvements on our rides.”

Intamin, Liseberg and sustainability

An example of this innovation & improvement can be found at Liseberg, a popular amusement park in Sweden.

“Liseberg and Intamin have partnered on projects for almost 30 years,” says Andreas Andersen, CEO at Liseberg. “We have quite a few attractions in the park that are a result of this partnership. What we value from Intamin is of course the high quality of the product, but also the flexibility and continued commitment to innovation.”

One thing that Intamin and Liseberg have in common is their commitment to sustainability.

“Sustainability is a very integrated part of our strategy,” says Andersen. “We have the ambition to be one of the world leaders in sustainable park management. Any innovation that can facilitate this journey is very welcome.

It is becoming more and more important for Liseberg to seek suppliers who can demonstrate that they are committed to developing more sustainable approaches to attractions, he continues, as it will with most other parks, at least those owned by large financial institutions or covered by new legislation, like the EU CSRD and EU Taxonomy:

“If you want to get financing in the future, you need to have a structured and ambitious approach to sustainability. The biggest push will come from the financial market – not from consumers. This will impact procurement and tender processes – and as such, have consequences for all suppliers.”

Quality = longevity

Benito Pellicer adds:

“Liseberg is for sure one of our clients who has been addressing sustainability for quite some time already. Liseberg always went for the newest proven technology and at the same time the highest quality available when it comes to rides, and it still does so to this day. And those two criteria most often also translate to sustainability. Why? Because they normally mean a long lifetime.”

A good example in this context is Balder, the Intamin-built wooden roller coaster which opened at Liseberg in 2003. It was the second installation utilising Intamin’s prefabricated and laminated wooden track, which was revolutionary at the time.

This technology promised a much longer lifetime for both the wooden track and also the support structure compared to conventional wooden roller coasters, where the operator often needs to start replacing the track and structure soon after its opening, and continue to do so in a permanent process that eats up a lot of resources.

Intamin’s product lived up to that promise. It was until after almost two decades of operation that Liseberg needed to replace the track sections.

Loke at Liseberg

A more recent example is Liseberg’s giant Intamin Gyro Swing, named Loke. This is one of the most popular rides at the park.

Intamin’s Gyro Swing is a stationary pendulum/swinging ride with impressive dimensions. It is the first ride of its kind to offer guests the sensational feeling of a suspended seat arrangement combined with the classic swinging and rotating movement. During their ride, guests experience the combined sensations of weightlessness, airtime and speed, as well as enjoying great views.

The ride also features a unique regenerative drive from the technology partner Inautec. Electricity is recovered from slowing and stopping the ride at the end of each cycle. It is then fed back to the local power grid, which can be reused by other consumers. This is an interesting approach to using energy that would otherwise be wasted by dissipating it on electric resistors.

“In the Gyro Swing model, the regenerative drive can recover up to 1.4 kWh of electricity per cycle. This corresponds to about 40% of the power needed by the motor to swing the pendulum,” explains Benito Pellicer. “If preferred, part of this electricity could be saved on a storage system to be directly used in the next ride cycle.”

A regenerative drive

The obvious benefit of the Gyro Swing’s regenerative drive is the operational cost savings due to returning electricity to the grid or saving it for the next cycle. However, adding an element of sustainability to a ride also allows Intamin’s client to communicate a positive message, both internally to the employees and externally to visitors and investors.

Andersen says that he is pleased with this innovation. He adds that it is a good example of how power-saving measures can be integrated into ride design: “This will be a hygiene factor for all ride manufacturers in the future when it comes to power and water savings, supply chains, etc.”.

When it comes to the future of sustainable ride technology, he adds:

“There will be a big push from investors to push this agenda forward, changing the way we purchase attractions.”

New innovations in sustainability at Intamin

Intamin is known for being a ride innovator. The Gyro Swing is just one example of how the company is applying new technologies that make its attractions more efficient.

“We use the same technology in our Gyro Swing rides built in Denmark and Finland, and in other models such as the Parachute Towers,” says Benito Pellicer. “Regenerative drive systems can also be implemented on roller coasters. The best examples are our Family Launch Coasters and our Hot Racer. Here, we use friction wheels to brake the vehicles at the end of the ride. This allows us to recover energy, like a dynamo on a bike.”

“Some additional examples of our more efficient technology developments are our magnetic braking and our LSM launching system, amongst others.

“With our network of partners, we listen to our clients to understand their desires and expectations. And then we find innovative ways how to fulfil them. For instance, out of conversations with clients, we are working on our CO2 emission calculations to help them complete their Scope 3 more accurately.”

Small changes can make a big difference

As well as these large innovations, the firm is also constantly making small changes in order to improve its designs. For instance, optimising material usage, changing to lighter materials like carbon fibre and aluminium, increasing energy efficiency, and reducing maintenance needs.

“For example, in 2021 Intamin & Stengel won the Red Dot Product Design Award “Best of the Best” for our new track design. This is more material efficient due to simplified fabrication and longer spans between columns,” says Benito Pellicer.

“However, making our products more sustainable is a balance and, as amusement rides manufacturers, we cannot take decisions hastily. Our priority is the safety of our rides. Most of the time, there’s a trade-off between performance and sustainability. That’s why it can be challenging to find suitable, more sustainable alternatives, as they may not meet the required performance.”

Sustainability at Intamin

In addition to its evolving rides, Intamin is also making internal changes to improve its sustainability.

“It is important to act not only in ride projects but in the way of operating and improving facilities,” says Benito Pellicer.

“Over the years Intamin has performed internal actions in its facilities and its manufacturing partners. For example, by implementing photovoltaic panels that cover about a third of their energy needs, upgrading traditional lighting to self-regulating LED technology, retrofitting ventilation systems with filters for recirculation, construction of a new energy-efficient assembly and testing hall, and others.”

“In the offices, we have implemented small actions to increase awareness. For instance, avoiding bottled drinks by promoting tap water with a free drinks dispenser, using soya milk at the coffee machine, and offering vegan and vegetarian to-go meals. We are also transitioning to a paperless office by implementing digital solutions.

“They may seem simple actions but still, moving towards a sustainable future requires substantial planning, time and economic effort.

A greener future

Looking ahead, Intamin is setting ambitious goals that will keep sustainability at the forefront of its operations

“In 2023, we created a Sustainability Office formed by two members. This will set a structure and organise the sustainability efforts at Intamin and its network of partners.

“This year, we aim at calculating Scope 1 and 2 emissions and raising awareness within the company and its partners. We are also working on finding out our product carbon footprint, to identify potential areas of improvement and to set reduction goals for the next years.”

To find out more about Intamin’s sustainable innovations, contact the team via email.