The business of attractions, straight to your inbox!

Sign up to receive the industry’s most comprehensive news service directly to your inbox every day.

✅ Thank you! We’ve sent a confirmation email to complete your subscription.

Project creator(s)

Entered into the following categories

Robotic Valve Unlocks New Design Possibilities for Water Feature and Special Effects Creatives.

The SplashValve robotic water switch, developed by Texas-based SplashBotix, is redefining how aquatic designers and special effects teams move water.

Drawing on industrial robotics system design principles, it is the first fountain technology to deliver independent nozzle height control within single-pump, manifold-based water features. Previously, this level of control was only possible among costly, high maintenance distributed submersible effect pump systems. Now, SplashValves offer creatives the same programming freedom and creative flexibility without the complexity and expense of multi-pump systems.

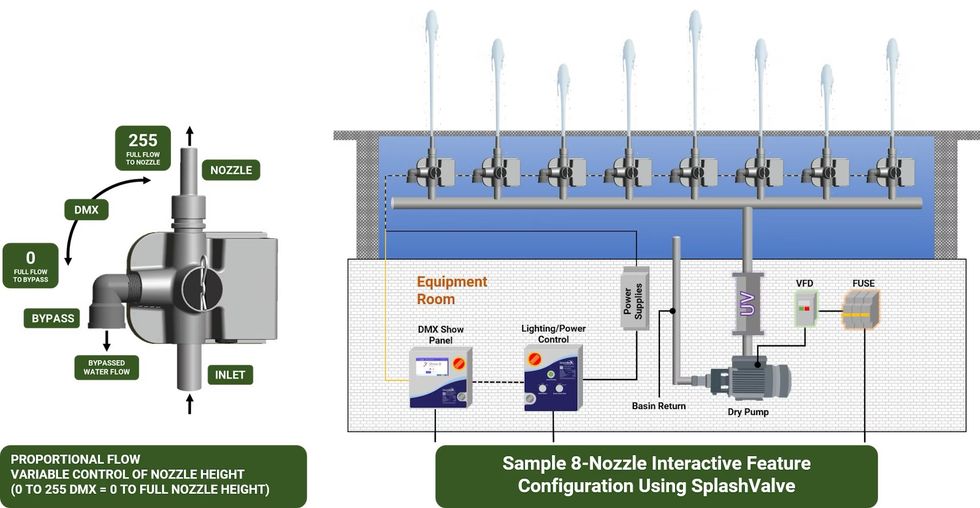

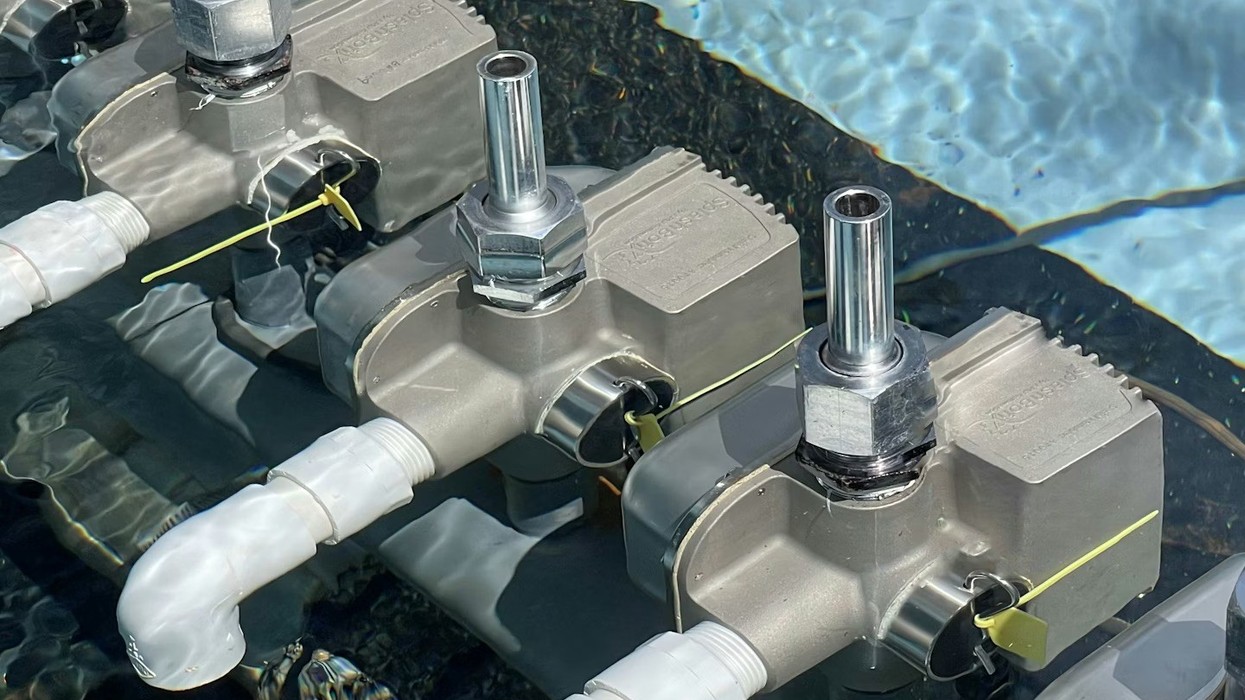

Low voltage and inherently safe, the SplashValve iterates on an older nozzle sequencing technology called the water switch, a three-way manifold-mounted valve installed beneath each nozzle that uses a pilot valve to channel incoming water to the nozzle or back into the fountain basin (bypass). The SplashValve improves on this technology by allowing programmers to channel water to the nozzle, to bypass or to varying proportions of both flow paths, enabling independent on/off nozzle sequencing and height control.

Inspired by the World of Industrial Robotics

The secret behind the SplashValve’s advanced flow control capabilities lies in its clever electro-mechanical design. Instead of a pilot valve, the SplashValve uses a specially designed, servo-actuated diverter valve. Set inside the SplashValve’s bore, the diverter rotates 90-degrees between effect and bypass, incrementally changing the nozzle spray height as it changes position. Motion is transmitted from the servo motor to the diverter valve via magnetic coupling, a clever design that allows for the SplashValve's motor and electronics to be completely sealed from the wet environment.

A division of industrial robotics firm ARM Automation, SplashBotix designed the SplashValve using many of the same industrial engineering principles its parent company uses every day. SplashBotix's approach to developing the SplashValve challenges assumptions about where advanced industrial robotics principles can provide value—not just on factory floors, but in interactive water features, too.

Unlocking Creative Flexibility

By enabling independent nozzle height control in manifold-based systems, the SplashValve is making it easier for designers across various disciplines to deliver exciting and immersive aquatic attractions.

Splash Pads and Interactive Water Features: In March 2025, Atlanta’s Fountain of Rings reopened following a renovation led by the Fountain People that replaced 220 water switches with SplashValves, culminating in the largest SplashValve installation to date. Today, the historic manifold-based fountain incorporates previously impossible choreographies like undulating wave patterns and fireworks-like effects in which slugs of water collide in mid-air. The SplashValves also allowed designers to dynamically set the rings to varying spray heights, bringing an entirely new dimension to the iconic interlocking ring motif. It's also allowed programmers to create different experiences for different patrons simultaneously, designating some rings as safe, low flow play zones for young children while others feature more dynamics effects meant to engage older kids and adults.

Themed Entertainment and Special Effects: In another project designed by Martin Aquatic and opened in July 2025, SplashValves were used to animate a series of Peanuts-themed interactive water features at Charlie Brown’s River Raft ride at Carowinds Amusement Park. Distributed across the 10,000+ square foot ride basin, the themed water features are connected by a single manifold fed by just one feature pump. Despite using just one pump for the whole system, ride designers were able to precisely program the spray trajectory of each feature, allowing them to surprise raft riders with well-timed sprays of water as they float through the attraction.

Delivering Code-Compliant Interactive Aquatic Experiences

The SplashValve comes as modern building codes make it increasingly harder for designers to specify distributed pumps in public water features. In states like Florida and California, codes stipulate that water sprayed from IWF nozzles needs to be treated with UV or chemical disinfectants prior to discharge. Distributed pumps pull directly from the fountain basin, making it virtually impossible to maintain compliance without installing a UV lamp or chemical feed at each nozzle. In a manifold-based system, designers can properly disinfect water prior to discharge for multiple nozzles using just one UV lamp or chemical feed for the entire system. Manifold-mounted valves like the SplashValve, therefore, present the only code compliant solution today for achieving variable nozzle height control in public interactive water features.

Partners

SplashBotix by ARM Automation, Inc. Development Team:

- Principle Design Engineer - Senior Design Engineer, Damian Hendriks

- Electronics Design and Software Engineer - Chief Technical Officer, Dr. Joe Geisinger

- Product Design Manager - Program Director, Ronn Garland

Fountain of Rings Design Team/Specifier:

- The Fountain People, Inc.

Carowinds Charlie Brown's River Raft Blast Design Team/Specifier:

- Martin Aquatic

blooloop is taking climate action and is now B Corp Certified.Sustainability strategy

Become part of the blooloop community:Work with us