Since 1980, Garmendale Engineering has provided world-class theme park engineering. As a successful family-run firm, it has built a reputation for handling complex, demanding projects while prioritising its core principle: engineering for longevity.

Specialising in the design, development, and delivery of ride systems and services, Garmendale offers a broad array of solutions, including ride systems, show control equipment, and essential park services such as maintenance, installation, and refurbishment.

Its extensive knowledge of the leisure engineering sector has established Garmendale’s standing as a renowned underdog in the theme park engineering world.

Having recently shared more about its unique origins, the company is now focused on the future. We speak with managing director David Shelmerdine and commercial director Zoe Shelmerdine about how Garmendale is expanding its skill set and deepening its engineering capabilities, while remaining true to the values that have defined it for over four decades.

Engineering that is built to last

The genesis of Garmendale’s ride manufacturing arm wasn’t driven by a desire to create flashy new products, but by necessity: the need to maintain and improve rides to ensure they could stand the test of time. David Shelmerdine’s background, having trained as an engineer and overseen the build of the original Dale Works workshop, underpins this pragmatic foundation.

That focus on practical, honest engineering — doing things the right way rather than the easy way — has been the foundation of Garmendale’s reputation ever since.

Zoe Shelmerdine explains: “We’ve had the privilege of working on some incredible rides over the years, keeping them running safely and reliably, by bringing together our engineering mindset and a deep understanding of how these systems perform in the real world.”

This focus on safety and durability is deeply personal, she adds: “As a family business with children, we always ask ourselves: ‘Would I put my child on this ride? What can we do to make it safer? To make it last longer?’

“Our engineering has always been built for longevity and safety.”

That same philosophy continues to guide every new project today, engineered not just to impress, but to endure.

Turning vision into reality

This belief means that Garmendale has stood firm on its values, never cheapening the product to cut costs, and instead building for longevity and safety. However, translating ambitious creative concepts into a budget-friendly, safe, and durable reality is often a balancing act.

“There are designers out there pushing every boundary, and that’s where we sometimes end up being the ‘bad guys’,” says David. “We’ll be in meetings full of creatives imagining how everything will move and light up, and then we have to bring it back to practicality: can this actually be done safely?

“We revel in the opportunity to find the happy medium between the dream and the reality”.

“We once had a walk-through experience design where items were placed all the way around a circular path,” says Zoe. “From an engineering perspective, guests could easily put an arm out and get caught between moving parts. We had to say, ‘No, that’s not safe.’

“So yes, it’s always a push and pull between creative ambition and engineering reality.”

The company’s long history of maintenance informs every aspect of its design process.

“Everything we design is built with how it will live through its lifecycle in mind, and how it can be serviced easily,” says David. “Maintenance, safety, and longevity are always front of mind.”

That mindset reflects a wider Garmendale philosophy: every creative idea deserves an engineering solution that lasts, not just one that works for opening day.

As ride concepts become more complex, this balance between creativity and engineering discipline will be crucial in ensuring innovation remains safe, sustainable, and achievable.

This driving ambition to continue revolutionising ride safety is a key driving force in the next phase of Garmendale’s worldwide growth.

Engineering experiences that bring people together

As technology, such as AI and automation, continues to shape attractions, Garmendale sees a clear trend back toward shared, physical experiences —something the company has always championed. For Garmendale, rides are about connection, not spectacle; about families sharing moments that last as long as the rides themselves.

“A few years ago, the big trend was VR and computer-generated experiences. But now I’m seeing a bit of a reversal,” says David. “People want to go to theme parks and share experiences with the person next to them, be it a friend, a parent, or a grandparent.”

He believes that while VR can be enjoyed at home, people want something real at the park. “I think we’re seeing a return to traditional rides, like coasters, merry-go-rounds, and rides that are simple, physical, and social.”

Zoe attributes this shift to changes in visitor demographics. “Grandparents are increasingly taking grandchildren to parks. Our family rides aim to entertain both, and we pride ourselves on the possibility that our rides may play a small part in creating an everlasting family memory.

Garmendale’s long-standing focus on reliable, multi-generational attractions makes Garmendale the perfect team to meet this renewed demand for real, shared fun.

Other key industry trends include sustainability and accessibility, both of which are long-standing priorities for Garmendale.

“We’ve always believed in building for longevity,” says Zoe. “We’ve got rides still operating from as far back as 1999. That’s sustainability to us; products that last decades.”

Durability and quality, while sometimes costing more upfront, pay off in reliability and customer satisfaction.

The company also maintains a strong focus on accessibility, integrating ADA involvement from the design phase.

“Even when we were building trains for a major UK manufacturer,” recalls David, “my father [Garmendale founder Roy Shelmerdine] refused to put ADA passengers in the back of the train. He insisted they should be right behind the tender, in the first carriage.”

That early commitment to accessibility has become an integral part of Garmendale’s design philosophy.

“We’re also seeing more retrofitting, creating designs that add accessibility or age-range capacity to existing rides,” adds Zoe. By designing rides that last for decades and can be easily maintained or upgraded, Garmendale isn’t just building sustainably, it’s future-proofing its products.

Reliability by design

For operators managing thousands of daily guests, reliability is non-negotiable. Garmendale ensures this through rigorous compliance and design discipline.

David explains that Garmendale has always designed to meet the Machinery Directive, even before it became an industry standard. The company now works to both EN and ASTM standards, ensuring global compliance and reliability.

“When we began working in North America, they understood immediately,” says David. “Now our processes align with both EN and ASTM standards.”

Garmendale’s internal processes are continually strengthened through the adoption of strict quality management systems. It introduced ISO 9001 quality systems into the business, even as a small company in the early 2000s, which has driven daily, weekly, and monthly growth through a focus on process and documentation.

This meticulous documentation offers significant operational benefits to clients. “Just this morning, a client contacted us about a coaster we built three years ago. They needed drawings and documentation, and we had everything, instantly,” says David.

It’s this kind of dependability that has cemented Garmendale’s reputation as a trusted partner to some of the world’s leading parks.

Garmendale’s culture of quiet confidence

The low staff turnover at Garmendale is striking, with many key team members spending their entire careers within the business. This stability, according to David, is maintained by treating every employee like family:

“If there’s a problem, we get around the table and solve it as a team. I’ve seen other companies grow fast and lose that, but we don’t have a ‘firing gun’ culture. We have a ‘let’s figure it out together’ culture.”

The long tenure of staff, who stay for decades, is a strong indicator of the company's integrity and environment.

“The industry itself is exciting, and we share that,” says Zoe. “Challenges help us grow. Things go wrong in every business, but we embrace them, learn from them, and come out stronger.”

That collaborative, family-driven approach continues to define Garmendale’s success and will be central to its future growth.

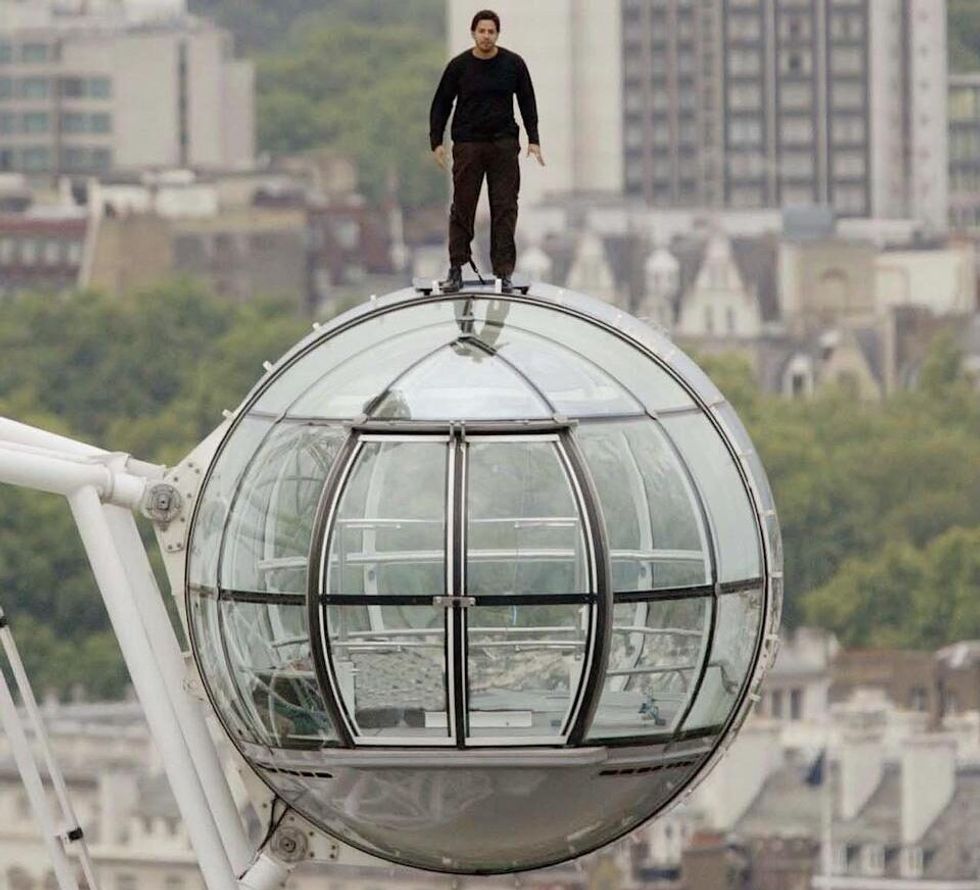

David Blaine on the London Eye - with Garmendale's engineering support

David Blaine on the London Eye - with Garmendale's engineering support

Despite working with the industry's biggest names and receiving phenomenal repeat business, Garmendale has always preferred letting its work speak for itself. “Getting the job done will always be part of our DNA,” says David.

“Engineering isn’t glamorous,” adds Zoe. “It’s always behind the smiles. I don’t think we’ll ever be the ones with the flashy booth in the middle of a trade show, and that’s okay. Our goal is for people to say, ‘What Garmendale builds is solid. What they promise, they deliver.’”

The company’s reputation for reliability and craftsmanship has even led clients to write Garmendale directly into their internal engineering procedures. Increasingly, the company is also known for helping parks maintain legacy attractions by reverse-engineering discontinued parts.

“The OEM might not be available, but we are,” says David.

“Our design packages often exceed client requirements because we’re constantly updating our software and systems. We’re right up there with the most prominent manufacturers — punching above our weight, and proud of it.”

Investing in tomorrow’s talent

Garmendale is also actively investing in the future to address the significant skills gap facing the industry, particularly in hands-on engineering in manufacturing.

“We invest in young engineers, from academic routes all the way through to hand skills,” says David. “The hands-on skills are especially important to me, because that’s where I started: on the workshop floor, working my way up to running and driving the business forward.”

The company has implemented multi-tiered training programmes to foster this skill base.

“We see it as an opportunity to give back to the industry,” says Zoe. “With our solid background, we can now offer training that caters to different skill sets.”

Refurbishing a traditional tram at the Dale Works facility

Refurbishing a traditional tram at the Dale Works facility

Recognising that individuals learn in different ways, David says the company aims to create a comprehensive training ground. “Right now, we’ve got two apprentices, one going down the tradesman route and another starting there before moving into the academic route next year at university.”

The challenge, he explains, lies in balancing digital design with practical fabrication: “There’s a massive push toward building things virtually with computer models and simulations, but what’s often neglected is the difference between designing something digitally and actually fabricating it in real life.

“Knowing the tricks of the trade to turn a virtual model into something you can sit on and ride is vital. Kids today are incredibly tech-savvy, but how many are weld-savvy? That’s the gap we’re working to fill.”

“For me, it’s about passing on the expertise we’ve built over 35 or 40 years, from design and quality control to shop floor skills, to the next generation.”

By combining digital fluency with hands-on engineering expertise, Garmendale is preparing its team for the next era of ride technology, from advanced fabrication and mechanical design to practical approaches for increasingly connected ride solutions.

But training the next generation isn’t just a business priority; it’s a continuation of the same values that started Garmendale: craftsmanship, care, and pride in doing things properly.

Keeping people moving

Looking toward the future, Garmendale’s focus remains clear: to leave a lasting legacy built on people, expertise, and shared experiences. “We want to leave a legacy of engineers and smiles,” says David. “Engineers who started with us, no matter where they go, will carry that solid foundation and knowledge.”

Garmendale engineered track for Jurassic Park Exhibition

Garmendale engineered track for Jurassic Park Exhibition

It’s a legacy that’s already three generations strong.

“A few months ago, I met a man about my age with his grandson,” recalls David. “He said, ‘This is the guy who built the track at Sundown,’ and his grandson said, ‘That’s my favourite ride!’ That particular ride has been operating for 26 years and has been enjoyed by three generations. That’s what it’s all about, families sharing experiences together.”

Zoe summarises their mission simply: “Keeping people moving, safely and happily.”

With the next generation of the Shelmerdine family now involved, and a clear vision for cultivating the next wave of hands-on, highly skilled engineers, Garmendale Engineering is set to continue its role as a quiet yet essential pillar of the global attractions industry. One grounded in honesty, built for longevity, and always engineered for the next generation of smiles.

Top image: Garmendale produced and supplied all of the steelwork as a subcontractor, while The Deluxe Group produced all of the FRP

Derek Morris and Steve Boney

Derek Morris and Steve Boney

Mark with family, Trust staff and St John Ambulance at the lion enclosureBuckinghamshire Healthcare NHS Trust / ZSL

Mark with family, Trust staff and St John Ambulance at the lion enclosureBuckinghamshire Healthcare NHS Trust / ZSL

David Blaine on the London Eye - with Garmendale's engineering support

David Blaine on the London Eye - with Garmendale's engineering support Refurbishing a traditional tram at the Dale Works facility

Refurbishing a traditional tram at the Dale Works facility Garmendale engineered track for Jurassic Park Exhibition

Garmendale engineered track for Jurassic Park Exhibition