As a former operations director, I admit that inventory management may not be the flashiest topic in retail, but for organizations focused on operational excellence, it’s foundational. And it is one of the topics that ops folks are obsessed with.

For retailers, inventory accuracy directly impacts replenishment efficiency, sales performance, and guest satisfaction. At Event Network, our annual Fall inventory process, referred to internally as “Inventory Season,” is an orchestrated operation involving every store team, system, and process.

Through years of refinement, we have developed a framework that prioritizes preparation, training, and accountability. Below are some of the key strategies we’ve adopted to ensure accuracy and effectiveness.

1. Preparation is everything

Successful inventory begins long before scanning day.

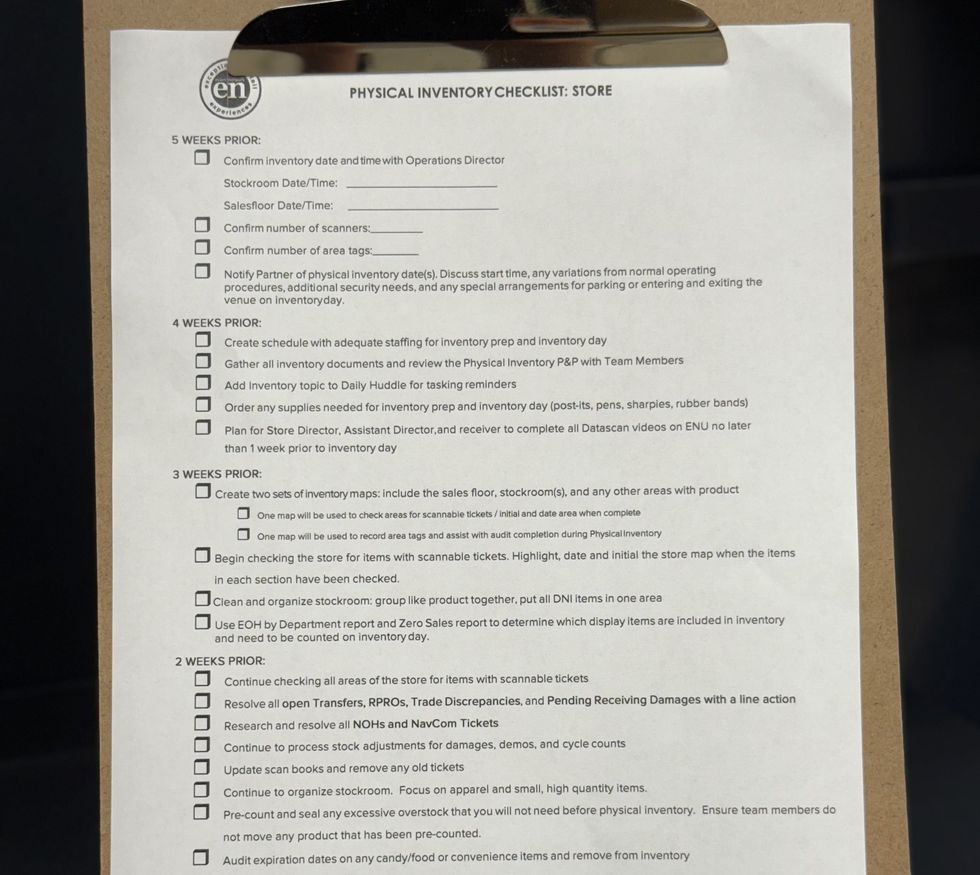

Store leaders utilize a comprehensive checklist that outlines preparatory tasks, including stockroom organization, accurate labeling, and securing necessary supplies. This proactive approach minimizes disruption and maximizes efficiency.

The checklist we’ve developed starts five weeks prior to inventory day and helps our store leaders manage their time by breaking the preparation tasks into manageable pieces.

2. Invest in training

Operational miscounts are often traced back to inconsistent training.

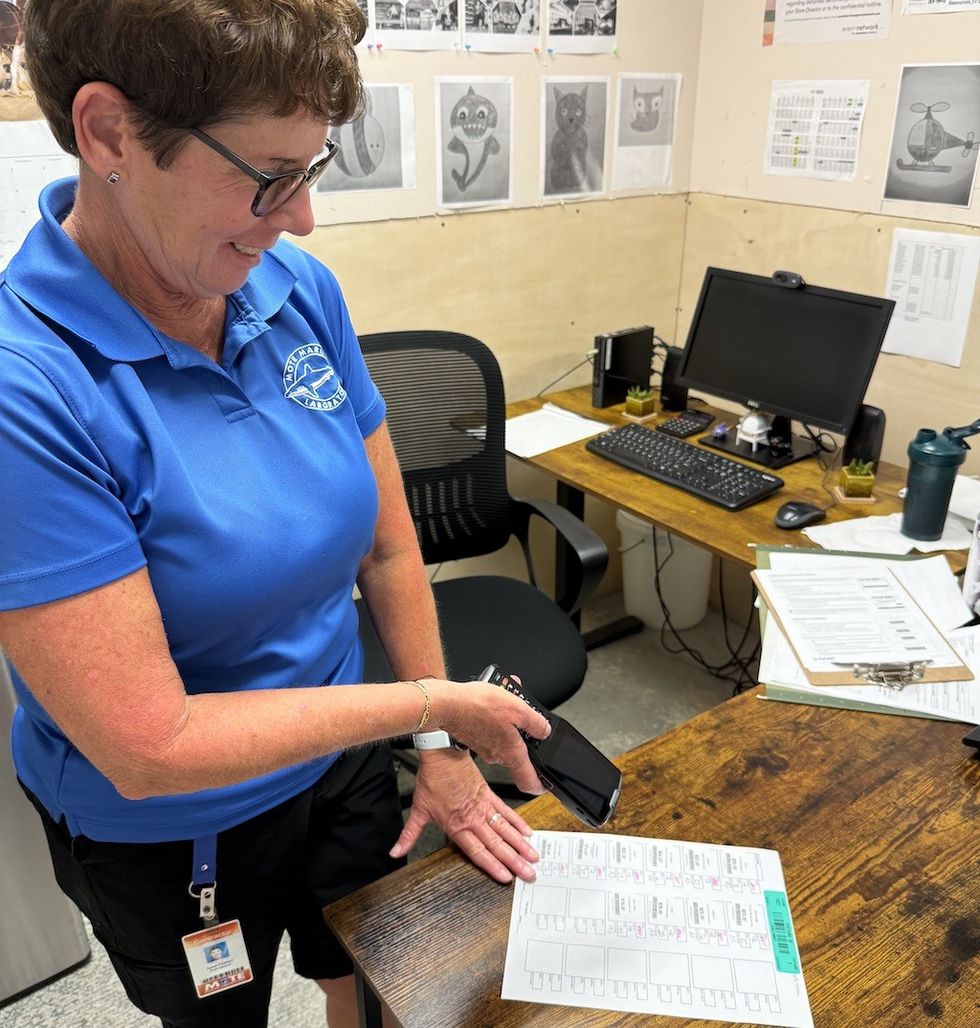

The inventory process we use emphasizes brief but targeted training sessions on scanning systems, inventory procedures, and common pitfalls. Empowering team members to understand the “why” behind inventory protocols leads to better engagement and fewer errors.

For our team members, one of the “why” discussions that resonates most with them is that inaccurate inventory numbers can harm product replenishment. Our teams never want to run out of bestselling items during the busy season.

3. Assign roles and zones

Clarity in responsibility is critical.

Each store maps out its sales floor and stock areas, breaking them into zones and assigning them to trained team members. This zone-based method ensures full coverage, minimizes overlap, and speeds up the auditing process.

We’ve also learned that it’s helpful to have one team member lead the map-making and auditing process. The map will be one of the most consequential tools on inventory day.

4. Plan for the unexpected

Contingency planning is a priority. Backup scanners, tested equipment, and overstaffing mitigate the risk of operational delays. Flexibility in scheduling ensures team members can manage any setbacks without compromising accuracy.

Unlike a typical workday, where team members arrive in shifts and lunch breaks are staggered throughout the day to maximize coverage on the floor, Inventory Day often works best when the group works as a unit.

Conducting a group training and orientation meeting, beginning the counting process together, and setting a lunch break time for larger groups helps keep the process running smoothly.

5. Maintain focused environments

Minimizing distractions during inventory is essential. Ambient noise is reduced, expectations are clearly communicated, and scheduled breaks are planned in advance to maintain concentration and morale.

We discourage team members from wearing headphones or having their cellphones with them during the counting process. In many cases, we even turn off the music in the store to maintain a focused environment.

Year-round inventory integrity

Ask anyone in operations or logistics, and they will tell you that the key to an efficient operation is having processes in place year-round to address potential issues.

In particular, maintaining inventory accuracy requires consistent year-round practices:

- Cycle Counts: Strategic weekly audits of high-value or high-loss items help preempt issues before they escalate.

- Receiving & Returns: Rigid adherence to receiving procedures and damage logging ensures incoming and outgoing stock is accurately recorded.

- Technology Utilization: Advanced inventory software supports real-time monitoring, alerts, and item history tracking to aid in root cause analysis.

- Daily Accountability: Team education around shrink, losses, and their role in maintaining inventory integrity fosters a sense of ownership and vigilance.

- Routine Spot Checks: Surprise audits on select items help reveal patterns and operational weaknesses.

Proactive shrink management

Shrink is the term most operations people use to describe inventory lost to theft, error, or system misalignment. These results, usually expressed as a percentage of loss relative to retail sales, are monitored post-inventory using comparative data.

Shrink categories include operational errors, internal and external theft, and data setup issues. Each store receives a customized shrink action plan with monthly follow-ups, performance tracking, and quarterly updates.

Because our Event Network core values focus on cultivating a culture of operational care, accountability, and continuous learning, we treat each instance of shrink as an opportunity for improvement.

Inventory, after all, is more than just numbers; it’s a reflection of retail excellence and the systems that support it.