Cloward H2O, an expert in aquatic design, views water chemistry management as the hidden engine of a thriving aquatic facility.

Behind every clear pool is a carefully engineered water chemistry balance. For developers, operators, and landscape architects, understanding water chemistry isn’t just maintenance; it’s key to sustainable design, safety, and cost efficiency.

Poor water chemistry can quietly damage infrastructure, increase operational costs, and harm reputations through user complaints or health issues. Conversely, a properly balanced water system protects materials, reduces the need for chemical intervention, and improves the visitor experience.

Cloward H2O shares the critical components of water chemistry management, offering practical insights into pH balance, chlorine efficacy, and long-term infrastructure protection, whether the project involves building a new aquatic complex, retrofitting a public park water feature, or managing a high-traffic hotel pool.

1. pH levels: the keystone of chemical balance

"Maintaining the pH of pool water between 7.2 and 7.8 is essential not only for swimmer comfort but also for ensuring the effectiveness of disinfection chemicals like chlorine," says the firm. In this range, chlorine works optimally to kill pathogens without becoming too aggressive.

Infrastructure implications include the effects of water pH on system components. Acidic water with a low pH accelerates corrosion in metal fixtures, pumps, and heating elements, which over time can lead to system failures and costly replacements.

Conversely, high pH or alkaline water causes scaling, especially in pipes and filtration systems. This scaling reduces hydraulic efficiency, thereby increasing energy consumption.

2. Chlorine levels: the fiirst line of defence

As the primary disinfectant, Free Available Chlorine (FAC) should ideally be maintained above 1.0 ppm to effectively control bacteria and viruses.

"Some jurisdictions vary in their minimum requirements, but essentially any measurable free chlorine residual signals that the baseline sanitation is handled, and the available residual is there to act against new contaminants that may be added," adds Cloward H2O.

Meanwhile, combined chlorine (chloramines) is a term that generally refers to chlorinated byproducts formed in a pool when chlorine reacts with ammonia and other bather-introduced contaminants, such as sweat, urine, and body oils.

"Ideally, no combined chlorine would be present, but that is challenging to maintain. Levels should be maintained below 0.2–0.3 ppm. Higher levels usually signal a problem indicating inadequate oxidation."

Levels above 0.5 ppm cause strong odours, eye irritation and even respiratory issues, especially in indoor aquatic environments.

The company says that a key operational strategy is to implement breakpoint chlorination or secondary sanitation systems (e.g., UV or ozone), especially in high-bather-load environments, to manage chloramine buildup and improve air quality.

"This is most critical for children’s pools, spray play areas, hot tubs, and any indoor aquatic centre or natatorium. Breakpoint chlorination involves adding enough chlorine to oxidise all organic contaminants and destroy chloramines, typically requiring a chlorine dose about 10 times the level of combined chlorine."

See also: Cloward H2O shares insights into what makes a successful water treatment system

3. Total alkalinity: the stability buffer

Alkalinity, ideally kept between 80 and 120 ppm, serves as a buffer against pH fluctuations. Without it, water chemistry becomes unpredictable and hard to manage.

"Operational impact includes the effects of alkalinity levels on water quality," says Cloward H2O.

"Low alkalinity results in pH fluctuations, which can cause corrosion, produce cloudy water, and create uncomfortable swimming conditions. Conversely, high alkalinity can stabilise the pH at undesirable levels and lead to scaling."

Chemical delivery systems should be automated, and operators must be familiar with measuring and managing TA in their water, taking into account the specific characteristics of the facility's water source and environment.

4. Calcium hardness: material protection in action

Calcium hardness, ideally between 200 and 400 ppm, safeguards pool surfaces and equipment from the harmful effects of soft water or the damaging accumulation of hard water.

"Soft water with low calcium content tends to leach minerals from plaster, tile grout, and even metal fittings, leading to etching and the premature degradation of finishes.

"In contrast, hard water with high calcium levels causes scaling in pipes, filters, and heaters, which reduces circulation efficiency and necessitates mechanical descaling."

Managing calcium hardness helps maintain the aesthetic quality of finishes in and around the pool, including decks, coping, tiles, and natural or faux stone.

5. Cyanuric acid: sunlight shield with a caveat

Cyanuric acid (CYA) plays a specific and often misunderstood role in outdoor aquatic facilities.

"Its primary function is to shield free chlorine from rapid photolytic degradation under sunlight. When used appropriately, it reduces daily chlorine loss; when mismanaged, it can significantly impair chlorine’s disinfecting power."

The recommended range is 15–30 ppm. "This revised range aligns with documented performance data showing that almost all measurable benefit from CYA occurs below 20 ppm, while higher concentrations substantially compromise chlorine efficacy," adds the firm.

Without CYA, accelerated chlorine loss occurs because sunlight rapidly destroys a significant portion of free chlorine within just a few hours. This forces operators to increase chemical feed rates to sustain the necessary disinfectant levels.

As a result, manual intervention and chemical expenses rise, since chlorine dissipates more quickly than systems can replenish it.

In outdoor pools, resorts, and water parks, where sunlight, rain, and bather load vary, automated systems are crucial. Real-time CYA monitoring or regular testing, combined with automated chlorine feed and ORP control, helps maintain effective chlorine levels and activity.

6. Secondary sanitation

Secondary sanitation is essential for the safety of recreational water. Using secondary sanitation methods enhances swimmer protection against potential pathogens that may resist standard sanitiser residuals.

Systems such as UV or ozone are especially important in busy or indoor settings where chlorine-resistant pathogens like Cryptosporidium pose serious risks. These systems improve disinfection without adding extra chemicals.

See also: Cloward H2O discusses secondary disinfection systems

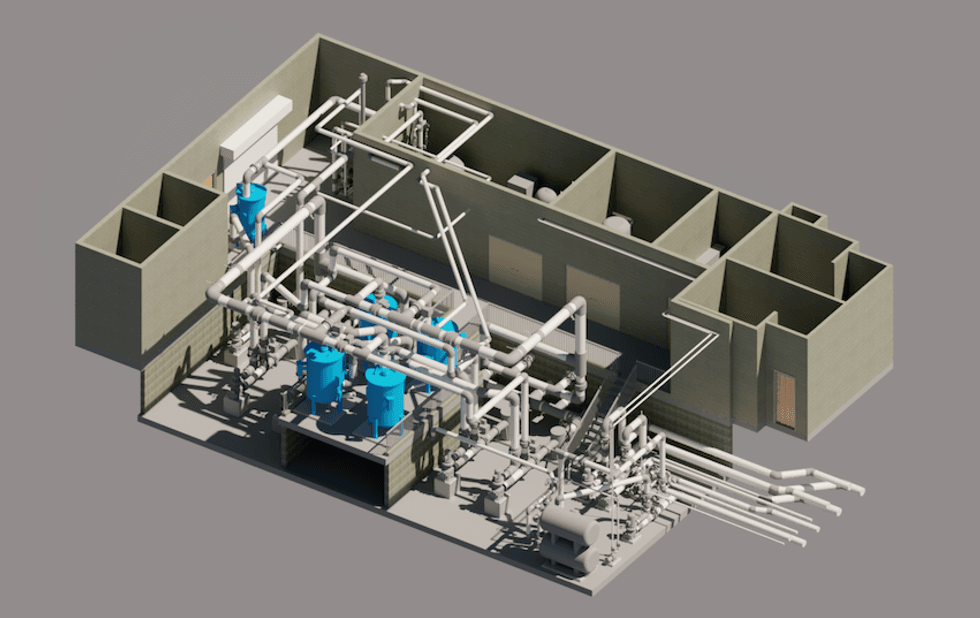

Designing smarter aquatic systems from the inside out

Effective water chemistry management is a collaborative process, not a checklist. Each chemical parameter influences the others and the broader ecosystem of a pool or water feature.

For developers and landscape architects, incorporating water chemistry considerations early in the design phase can prevent costly retrofits and service disruptions. For operators, regular monitoring and proactive adjustments maintain both the facility’s physical integrity and its public reputation.

"Ultimately, the clearest, cleanest, most inviting pools are not just the result of luck or budget—they’re the product of informed decisions, strategic system design, and thoughtful long-term planning," says Cloward H2O.

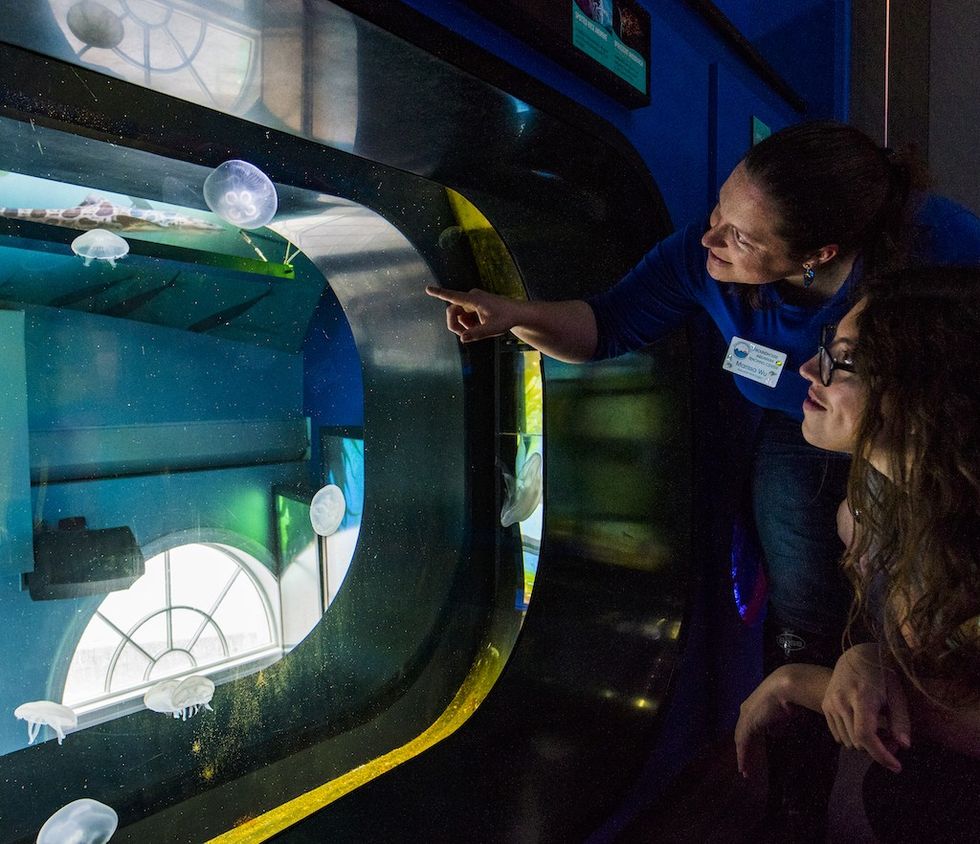

Recently, Cloward H2O also explored the art and science behind modern aquarium experiences, emphasising how engineering, animal care, and visitor expectations influence these intricate facilities, and sharing aquatic technical considerations to address when designing an aquarium.

Charlotte Coates is blooloop's editor. She is from Brighton, UK and previously worked as a librarian. She has a strong interest in arts, culture and information and graduated from the University of Sussex with a degree in English Literature. Charlotte can usually be found either with her head in a book or planning her next travel adventure.

Erdem Akartepe during the opening ceremony

Erdem Akartepe during the opening ceremony The first equipment manufactured at the new facility

The first equipment manufactured at the new facility

AeUrbia

AeUrbia  AeUrbia

AeUrbia  AeUrbia

AeUrbia