Founded in 2018, AquaRevival specialises in regenerative media filtration systems designed for the aquatics, food and beverage, agricultural, and industrial sectors. Its innovative systems deliver drinking-water quality while promoting sustainability and operational efficiency.

The company’s filtration solutions are NSF 50, 61, and 372 certified, ensuring safety and performance across various applications. Notably, its technology has achieved NSF certification for Cryptosporidium reduction, marking a significant advancement in recreational water safety.

Manufactured entirely in the US, AquaRevival's products are built using ASME-certified materials, reflecting its commitment to quality and compliance. By integrating advanced automation and energy-saving features, the firm offers clients a cost-effective alternative to traditional sand filtration systems, reducing water waste and chemical usage.

We speak to Paul Nehlen, president of AquaRevival, about how, with its focus on innovation and sustainability, the company continues to set new benchmarks in water filtration, providing solutions that meet the evolving needs of modern industries.

A passion for invention

Nehlen’s career includes decades with a Fortune 500 company, followed by time with a private equity firm that owned a competitor in the water filtration space. As head of engineering and operations, he helped grow the business, improved manufacturing, and filed patents, including a heat exchange patent, before leaving when the company changed hands.

An entrepreneur with a passion for invention, Nehlen has been building filtration pressure vessels and similar systems since the 1980s: “I started in a factory building compressed air and gas purification equipment when I was 17. I’ve been around welding and making heavy equipment for a long time.”

When founding AquaRevival, Nehlen started from scratch and designed a filter housing and internal filtration system specifically for water-based fluids.

“The filters our competition uses are based on regenerative filters that have been around for over 100 years. They were initially designed for the automotive industry. Later, the same design was adapted for dry cleaning fluid, and decades later, someone decided to use it for pools. But it was never designed for water.”

“The business literally started in my garage. I built the first filter, like Harley and Davidson did with their first motorcycle, in a shed. The neighbours got a kick out of it; they never know what I’m building next. Their kids come over, and we have science class in the garage.

“That’s how it all began."

AquaRevival: setting a new standard

The technology is revolutionary in several ways. As well as being the first system designed specifically for the industry, it is the first & only firm to achieve certification from NSF International, the leading testing and certification organisation in the water industry, to a new standard for Cryptosporidium parvum reduction.

This parasite causes severe gastrointestinal disease and cannot be killed by chlorine alone, posing a longstanding risk for places like water parks, swimming pools, and resorts.

“A few years ago, the NSF 50 language was amended to allow for the capture of Cryptosporidium parvum, and the Model Aquatic Health Code also has it written in,” says Nehlen. “Those are the two primary standards used in the US to determine whether a filtration system qualifies for commercial environments.”

NSF 50 specifically deals with water that humans will be in. It regulates everything from filtration to UV to chemical dosing.

“Nobody else had attempted a couple of things. One was that the filtration rate was increased by 50%. You used to be able to run only two gallons per minute per square foot of trade scenario, and they raised it to three. We tested and achieved that.

"We were the first and only company to reach three GPM per square foot for our filters. Our competitors limit their filters to 1.4 GPM per square foot. We are more than double their performance.

“That means our filters are much smaller for the performance you get. We take up less room in the pump room, which saves money on construction because facilities can use a smaller filter.”

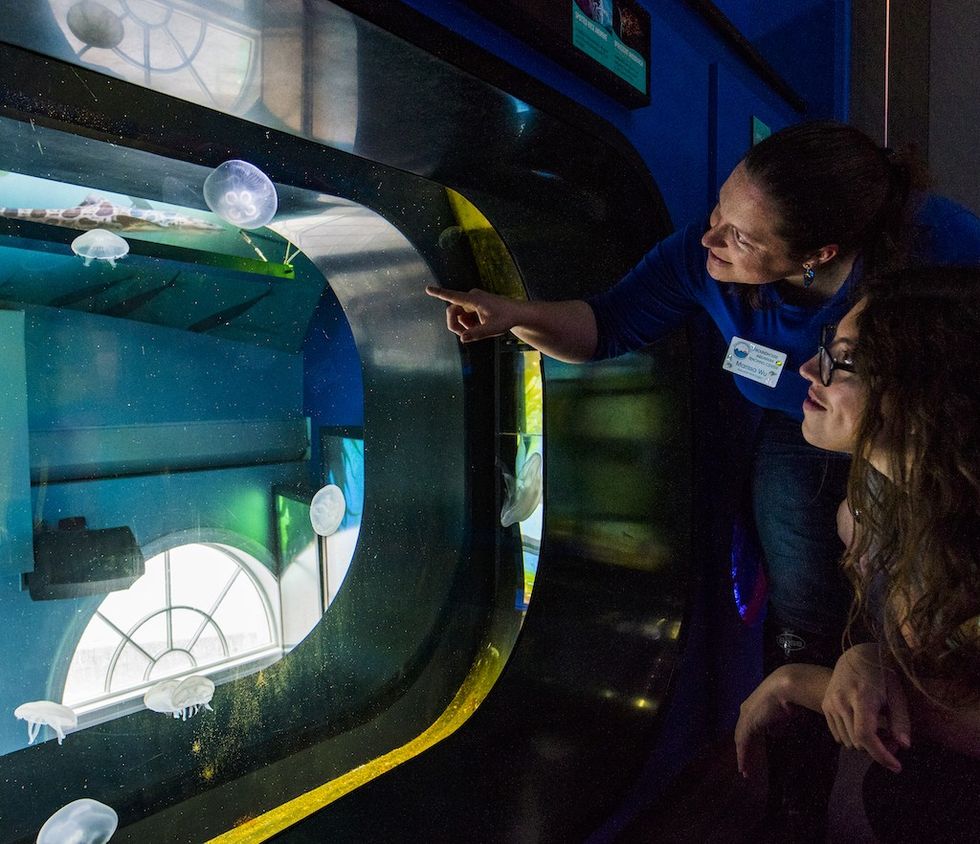

Safer swimming

Separately, the Cryptosporidium endorsement allows AquaRevival to demonstrate that not only is it filtering far more water per unit of time than its competitors, but it is also certified to filter Cryptosporidium, which is as small as one to three microns in diameter.

“Cryptosporidium can survive for days in chlorinated water. So, pools add UV systems, which unzip and inactivate the organism's DNA. But if your UV system isn’t working optimally, the Crypto keeps circulating through the system and back into the pool.

“The difference with our filters is that we remove 67% of the Cryptosporidium on each pass. The testing for this is precise. And because we capture the Cryptosporidium, it never ends up in a swimmer’s mouth, eyes, or mucus membranes. It gets disposed of, making your water unquestionably safer.

“That’s why it was written into NSF 50, and why the Model Aquatic Health Code envisioned that, someday, someone would come up with a process to capture it—and now we have.”

The Centers for Disease Control found that between 2009 and 2017, Cryptosporidium was the leading cause of water-related diarrhoea outbreaks in the US, accounting for 35% of these incidents and over half (56%) of reported cases were linked to contaminated water in pools or playgrounds.

While healthy individuals typically recover, infections can lead to severe malnutrition and wasting in immunocompromised patients.

“If you already have a compromised immune system, it can be lethal. It’s generally not fatal, but it can make you very, very sick.”

So, for operators, technology that effectively prevents Cryptosporidium outbreaks is a game changer.

The benefits of choosing AquaRevival

AquaRevival’s filter systems are easy to install, whether for a new project or refurbishing an existing facility.

“All of our filters fit through standard doors. That means we save money on tear-out because you don’t generally need to make changes to the building to get our filters in.

“For new builds, they can construct a smaller pump room, which translates to direct capital expenditure savings. These savings often cover the cost of the filters and more. Customers have even told us that by buying our filters, they built a smaller pump room, which more than paid for the filters, essentially making the filters free.”

Because it’s a smaller footprint, that space becomes monetisable, too:

“You could add a food and beverage stand, a shop, or more slides, all things that increase guest experience and generate revenue.”

Beyond public safety, there are additional operational and financial benefits, he adds:

“We’ve built a few features that nobody else has into our filters. We have photo-driven maintenance screens customised to local facilities. If there are language barriers, we use images. For example, the screen might show a specific valve and say, ‘Close this valve.’ Maintenance procedures are graphically shown in the controller, either attached to the filter or mounted on a nearby wall.”

This makes the system easy to operate.

“We choreograph all the other systems, chemical control, heaters, UV, through our filter controller. This allows us to control the system shutdown, media revival, and startup sequence in a way that ensures chemicals aren’t added when water isn’t flowing, and heaters do not build up water in the pipes during a shutdown scenario. It's a smooth, automated operation that requires minimal manual input.”

Reliability and ease of maintenance

AquaRevival also offers a 15-year warranty.

“Most warranties top out at 10 years, some only five. We use ASME Section VIII quality materials and have material test reports for all subcomponents. That costs us extra, but we do it for reliability. These filters run overnight when no one's around, so safety matters.

“Because our filters are smaller, you don’t need scaffolding or big ladders to work on them; everything can be accessed from the ground, which is safer for the maintenance team. We've thought through what happens after installation, when staff are left to operate the system alone.”

Post-installation, there is no need to take the filter apart to clean it:

“We use a patented Clean-in-Place (CIP) process, like in the food and beverage industry. Dairies don't disassemble everything when switching between milk, kefir, or yoghurt. They clean in place. We brought that process into this industry.

“Our system meets the new, very stringent NSF 50 standards for cleaning. It’s easier on operators, doesn’t require disassembly, and still achieves long filter runs with very low maintenance time."

Sustainability at AquaRevival

Sustainability is a big part of the company’s approach, too:

“Because our filters are smaller and we don’t backwash like traditional sand bed filters, we save a significant amount of water,” says Nehlen.

“In a sand bed filter, you reverse the flow to flush out the dirt, which can waste thousands, even tens of thousands, of gallons of water every week. We don’t do that. Instead, we 'revive' the media. That means we stop the pumps and shake the media loose so it and the trapped dirt go into suspension inside the tank. Then we turn the system back on, and it re-coats the filter elements.”

The key is that no water, chemicals, or heat (which the operator has already paid for) is lost during this process. “This all adds up to lower environmental impact. We can filter out particles as small as 1 micron, and in some cases, sub-micron, and of course, that includes Cryptosporidium. The water that comes out of our filter is sparkling clear, approaching bottled water quality.

“It’s a testament to the technology.”

An efficient solution

As the AquaRevival system captures around 67% of Cryptosporidium in the first pass, it is highly efficient. “Instead of running it repeatedly like some competitors, we get a bigger capture rate each time.

“We design the system to achieve 100% turnover of pool water in about 24 hours. So, if you have a 100,000-gallon pool and run 100,000 gallons through the filter every four hours, not every molecule passes through exactly once. Some go through multiple times. But over 24 hours, it balances out.”

He adds another critical sustainability point: “When we revive the media, we reduce the pressure inside the tank. These are surface filters, and as dirt builds up, it reduces the surface area available, increasing the pressure differential, with higher pressure in and lower pressure out."

“Once the pressure hits a set threshold, the control automatically stops the system, revives the media, and re-coats the elements. This drops the pressure again, so the pumps don’t have to work as hard. It is all automated.

“Early in the cycle, pumps run easily. As the filter loads up, they work harder to maintain flow. But we reset the pressure before it gets too high, so the pumps consume less energy overall.”

By reducing water waste, chemical use, and energy consumption, the technology supports a much more sustainable approach to aquatic filtration.

“A game changer”

One satisfied AquaRevival customer is MountJoy Aquatics, a leader in commercial aquatic distribution.

“Our goal is to advance the safety of public water through technology and innovation,” says Bart Mountjoy, president. “Aqua Revival’s industry-leading filters have helped us achieve that goal."

“Aqua Revival's willingness to challenge industry norms through technology and innovation has been a game changer for us. Additionally, their commitment quality and support make selling and supporting their products a no-brainer.

“The Aqua Revival filter is a top-to-bottom rethink of the regenerative media filter. Industry norms for facility types, flow rates, maintenance, and care have been changed with this filter. The NSF certifications, customer testimonials, and contractor loyalty speak for themselves.”

R&D and what’s next

AquaRevival’s approach to R&D is driven by time spent in the field with customers, says Nehlen:

“That’s how we’ve developed a deep understanding of real-world challenges. I’m an engineer by background, and over the years I’ve designed a lot of equipment. But I think people return because they enjoy working with us in the pump room. I listen. I won’t always have the correct answer immediately, but I’m relentlessly committed to finding it.”

The team works closely with customers not just to solve their problems, but to help them become experts themselves. “That way, they can deliver the best possible experience to their customers.”

R&D at AquaRevival spans several areas. “We’ve developed concepts we haven’t yet brought to market. There are some exciting technologies in the background, but our core focus has been on regenerative media filters, because that’s where we see the most significant impact for water parks: filtration that reduces water usage, saves energy, lowers chemical costs, and improves safety.

“Water is the single most crucial resource in this industry. If we can help parks use less water and fewer chemicals while improving water quality, we’re directly lowering their operating costs and environmental impact.”

The R&D process includes building physical prototypes, using computational fluid dynamics, and 3D modelling. “And even though we’re a small company competing against global giants, we’re leading the way,” he adds.

“We now hold nine US patents and patents covering the UK, Australia, and Japan. We are, without question, at the forefront of NSF 50 commercial aquatic filtration technology.”

As for what’s next: “I can’t share too much yet, but I can say it will be worth talking about. It’s a significant advancement that will help water parks improve their uptime and overall operations in a big way.”

Erdem Akartepe during the opening ceremony

Erdem Akartepe during the opening ceremony The first equipment manufactured at the new facility

The first equipment manufactured at the new facility

AeUrbia

AeUrbia  AeUrbia

AeUrbia  AeUrbia

AeUrbia