Cloward H2O, an expert in aquatic design, recently explored the art and science behind modern aquarium experiences, emphasising how engineering, animal care, and visitor expectations influence these intricate facilities. It now shares the aquatic technical considerations to address when engineering an aquarium.

Behind every impressive aquarium is a complex engineering foundation invisible to visitors but vital for aquatic health and facility success.

Cloward H2O knows that creating such environments depends on precise control of hydraulic flow, pressure, acoustics, temperature, and advanced systems. These must operate reliably under extreme conditions and align with each project's architectural and biological aims.

1. Hydraulic dynamics inside exhibit tanks

- Flow patterns and hydraulics: water flow in tanks must mimic natural environments, prevent dead spots, and ensure even temperature and oxygen distribution. Poor design can cause stagnation, harming marine life and clarity. Expertise is needed to optimise circulation and water movement to make them appear natural and effective.

- Inlet and outlet optimisation: properly placed inlets and outlets ensure debris and waste are removed efficiently without disturbing the aquatic habitat.

2. Acoustical considerations

- Noise control for sensitive species: aquatic animals, especially marine ones, are very sensitive to noise and vibrations. Engineering solutions should minimise noise from pumps, filtration, and visitors. Architects might overlook acoustical treatment in areas with vulnerable species. Cloward H2O engineers can design isolation systems and vibration-damping supports and incorporate acoustic materials into the design.

3. Thermal management

- Environmental temperature control: aquatic environments require precise temperature regulation across zones, like warm tropical tanks or cold-water displays. Managing multiple heating and cooling systems adds complexity, considering thermal dynamics.

- Heat load from lighting and equipment: powerful lighting generates heat, raising aquarium and ambient temperatures. Cloward H2O engineers incorporate heat load calculations to prevent temperature spikes that harm animals or waste energy.

- Heat recovery systems: aquariums often cool water due to environmental and equipment loads. The heat can be recovered for other building systems, reducing energy use.

4. Biosecurity and filtration system zoning

- Isolation of exhibits to prevent disease spread: different aquarium exhibits require biosecurity measures, such as compartmentalised filtration, UV sterilisation, and quarantine protocols. Engineers focus on controlling water flow and isolating systems to keep the entire aquarium healthy.

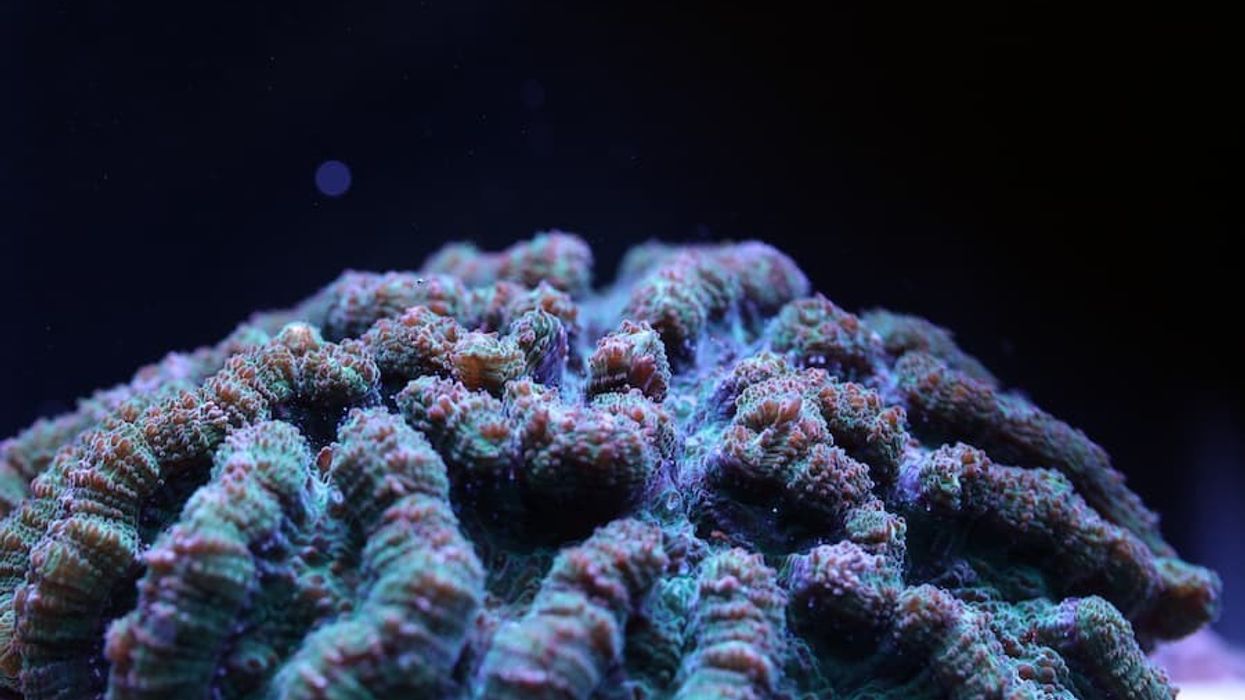

- Advanced filtration zoning: Cloward H2O designs filtration zones for various species' waste loads, requiring specialised equipment for the unique biological footprints of fish, coral, and invertebrates.

5. Advanced control and monitoring systems

- Automated control systems (SCADA): the ability to automate and remotely monitor life-support systems is vital for maintaining stable water quality and environmental conditions. Cloward H2O incorporates Supervisory Control and Data Acquisition (SCADA) systems that enable real-time monitoring, automated adjustments, and logging of critical data for trend analysis, ensuring immediate responses to deviations from optimal conditions.

- Data analytics for ecosystem management: modern aquarium systems benefit from data-driven insights. Cloward H2O engineers include sensors and monitoring devices in their drawings to collect data on temperature, pH, oxygen levels, and nutrient cycles, enabling staff to predict and prevent potential issues before they occur.

6. Waste management and water reclamation

- Closed-loop water systems: engineers design efficient water reclamation systems that filter and recycle water, minimizing waste and environmental impact. This is crucial in large aquariums with millions of gallons, where reducing water use saves costs and benefits the environment.

- Waste removal systems: handling aquatic waste is a challenge in aquarium design. Civil engineers create waste management systems to keep water clean and reduce the impact on sewage and ecosystems, including bio-waste digestion or safe discharge after treatment.

7. Tank structural design

- Structural integrity under hydrostatic pressure: every aquarium tank must withstand hydrostatic and dynamic pressures from contained water. Structural design involves calculating wall thicknesses, material strengths, and load distributions to ensure safety under normal and extreme conditions. In large aquariums, forces on panels can reach hundreds of tons.

- Material selection and performance: choosing the right material is crucial for exhibit tanks' durability and clarity. Acrylic, with its optical purity and strength, is preferred for large viewing windows and tunnels, capable of thermoforming into complex curves for immersive experiences while maintaining structure. Laminated glass may be chosen for smaller or specialised tanks, prioritising scratch resistance and rigidity. Selection involves evaluating UV exposure, chemical compatibility with seawater, and resistance to stress crazing or fatigue cracking.

- Seam and joint engineering: the seams of an aquarium are crucial structural parts that must withstand ongoing internal pressure and stay watertight for decades. Engineering analysis, often using finite element modelling, ensures that stresses around edges and corners remain within safe limits under seismic or operational loads.

- Thermal and structural expansion management: Large tanks undergo continuous size changes from temperature and hydrostatic forces. Without proper management, these can lead to fatigue or microfractures. Cloward H2O engineers include expansion joints, flexible seals, and temperature compensation to allow controlled movement while maintaining panel and seal integrity.

Tailored solutions for diverse needs

Whether the project is a small community aquarium or a sprawling marine park, Cloward H2O offers tailored solutions that meet each development's specific requirements.

The firm's versatile team can adapt to projects of varying scale and complexity, delivering results that exceed expectations. Staying ahead in aquarium design requires leveraging the latest technology and innovation. Cloward H2O uses advanced techniques to create visually stunning, functional aquatic environments.

Cloward H2O also promotes sustainability through eco-friendly, energy-efficient designs, creating environmentally conscious aquariums that enhance educational and conservation efforts.

In recent news, Cloward H2O shared details about the new Zion Shores project, an upscale surf-community development located just outside Zion National Park in southern Utah.

Charlotte Coates is blooloop's editor. She is from Brighton, UK and previously worked as a librarian. She has a strong interest in arts, culture and information and graduated from the University of Sussex with a degree in English Literature. Charlotte can usually be found either with her head in a book or planning her next travel adventure.

Before and after

Before and after