Designed to be an imagination box and a place of wonder, AREA15 is the world’s first purpose-built experiential entertainment district, minutes from the Las Vegas Strip.

Here, creativity and content flourish through best-in-class experiential entertainment companies such as Meow Wolf, Superplastic and Lionsgate's John Wick Experience. AREA15 is continuing to expand, with the upcoming Universal Horror Unleashed, Interstellar Arc, Museum of Ice Cream and more.

Innovation Awards 2025: celebrating innovation across the sector

The winners of the blooloop Innovation Awards 2025 will be announced at the Festival of Innovation. This is taking place online between 21 and 22 January 2026.

Registration is now open and is free.

The Festival will include panel sessions featuring leading operators and individuals behind the award entries. In addition, every award entry will be on display in our Innovation Showcase for attendees to view.

Ahead of the event, we share a look at some of the Innovation Award 2025 entries that will be showcased at blooloop’s Festival of Innovation.

Crocodile Island at Suntago Water World

CSB - Creative Studio Berlin has entered Crocodile Island in the Family and Storytelling categories.

Park of Poland

Park of Poland

A dry-play area at the centre of Suntago Water World in Poland, Crocodile Island blends immersive storytelling, sensory learning, and technology-driven interactivity.

Setting a new standard for themed water parks, the project combines on-land fun with an aquatic theme across four zones, each designed to serve different age groups from 3 to 16.

Arcade Arena Manchester - Pac-Man Live Experience

The Pac-Man Live Experience at Arcade Arena Manchester has been submitted to the Brand Realisation and Game On categories by Little Lion Entertainment.

The Pac-Man Live Experience launched in Manchester in March and has since rolled out to Arcade Arena venues in Dubai and Saudi Arabia.

Immersive technology transforms the venue into a life-size maze, where players wear high-tech vests with advanced tracking to become Pac-Man, collect pellets, and dodge ghosts in a physical, augmented-reality adventure.

Augmented Games

Moment Factory has entered Augmented Games in the Game On category.

Augmented Games, Moment Factory

Augmented Games, Moment Factory

Augmented Games is a smart, flexible gaming platform that uses full-body participation powered by intelligent motion-tracking technology to turn venues into dynamic, interactive playgrounds.

With adaptable configurations and a growing game library, it brings together the excitement of active play with the broad appeal of video games. Players navigate projected or LED surfaces without wearables or controllers in quick, intuitive games.

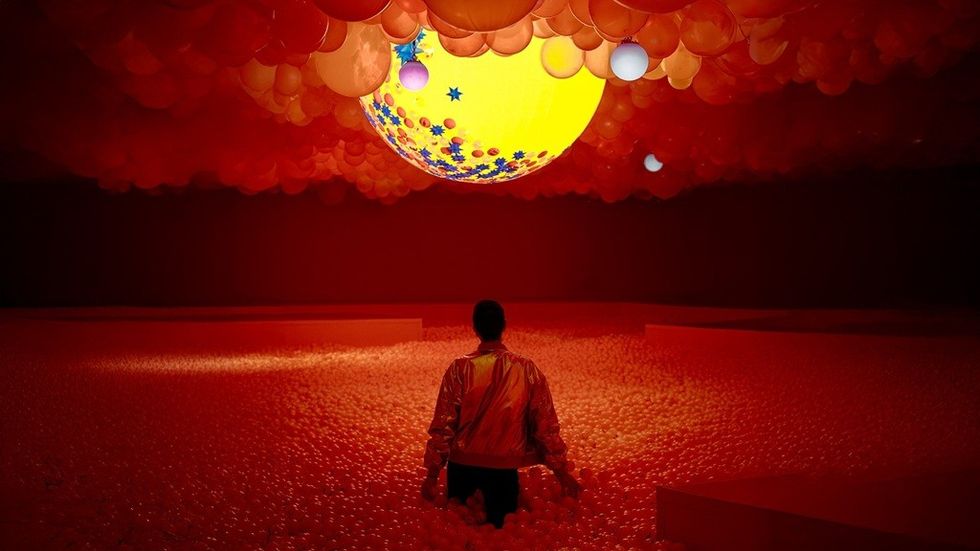

Balloon Museum

The Balloon Museum has been submitted to the Immersive Experience - Culture category by Lux Entertainment.

The accessible, genre-defining Balloon Museum merges high art and mass appeal in a participatory, experience-first format where leading contemporary artists use air to create art that visitors can enter, touch, and become immersed in.

Neither an entertainment pop-up nor a traditional museum, Balloon Museum represents a new cultural phenomenon that has transformed how millions of people experience contemporary art.

Bringing Attack on Titan to life: Fuji Airways Flying Theater

Brogent Technologies Inc. has entered Attack on Titan THE RIDE - Battle of Liberio in the Brand Realisation and Thrills categories.

Brogent Technologies’ partnership with Kodansha on Attack on Titan THE RIDE – Battle of Liberio brings the globally renowned anime IP into Fuji-Q Highland’s cutting-edge flying theatre, Fuji Airways.

Capturing the intensity, scale, and emotional depth of Attack on Titan as a fully immersive, real-world experience, it reworks key moments from the series into a seamless 360 degree journey where audiences can engage with the world as active participants.

Cercle Odyssey and Panasonic create a world first in immersive concert storytelling

This project has been entered into the Immersive Experience - Culture and Storytelling - Culture categories by Panasonic Connect Europe.

Inspired by Homer’s Odyssey in Greek literature, the Cercle Odyssey world tour has established a new standard for immersive entertainment that is mobile, meaningful, and sustainable.

A multisensory concert with 360 degree projections, music, cinematography, lighting, sound, and scent, Cercle Odyssey offers audiences a new type of immersive experience that delivers a powerful connection to the music and to each other.

Comets Landing: University of Texas at Dallas Esports & Gaming Center

AVI-SPL has submitted Comets Landing to the Game On category.

Comets Landing at The University of Texas at Dallas (UTD) is one of the largest and most advanced campus gaming and esports facilities in the US.

Built for both competition and education, the arena features 50 high-performance gaming stations, a professional-grade broadcast studio, and precision AV integration for live-streamed tournaments. Outside, an Absen LED video wall turns the common area into a viewing plaza for watch parties.

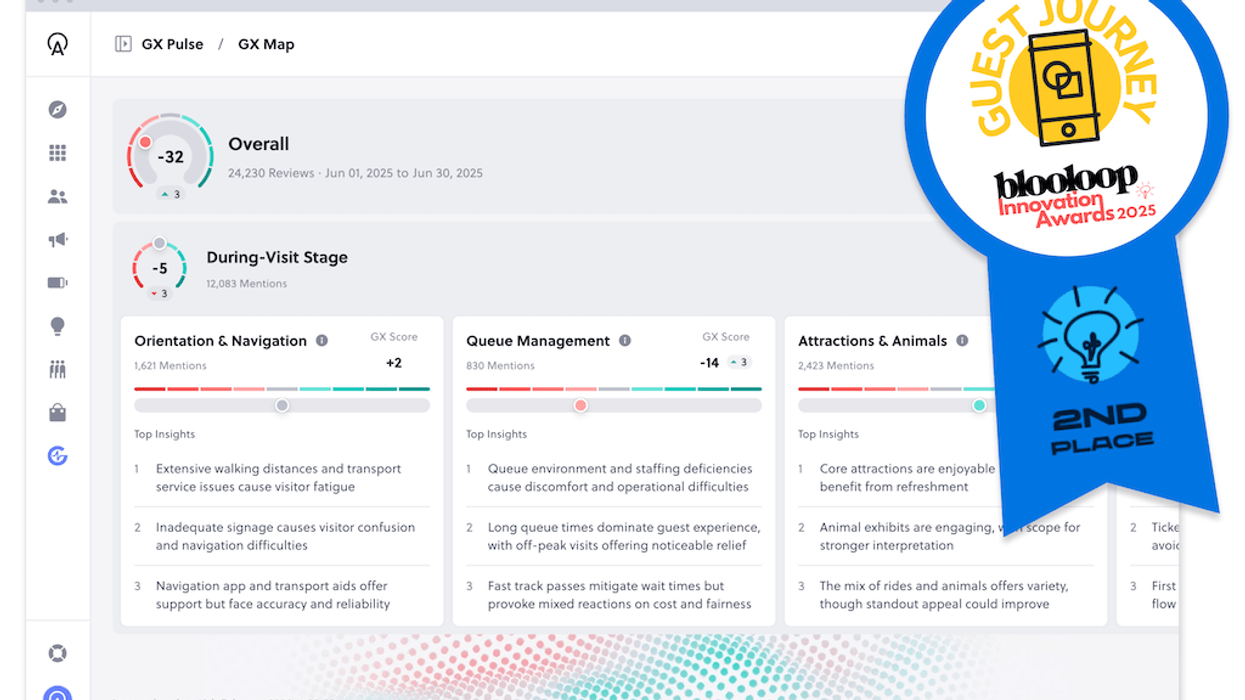

Connect&GO launches first fully integrated AI-powered dynamic pricing

The project has been entered in the Guest Journey category by Connect&GO.

eCom Calendar

eCom Calendar

AI-powered dynamic pricing from Connect&GO maximises revenue and manages crowd levels by analysing park data, weather, and demand.

It increases revenue by 14% through subtle 4% price adjustments, balances attendance across weekends and weekdays, reduces bottlenecks and improves safety while maintaining full operator control.

Digitisation of the Barcelona Aquarium enhancing the customer journey

This project has been submitted to the Creative Technology, Immersive Experience and Exhibit - Animal categories by TRISON.

Barcelona Aquarium has reinvented its visitor experience using digital technology to create a memorable, multi-sensory journey that combines education, entertainment, and wonder while respecting the fragile marine environment.

On the exterior of the aquarium visitors are welcomed by a huge LED screen. Inside, a 300-square-metre digital ocean deepens the emotional connection between visitors and the marine world, LED and LCD touchpoints enhance storytelling, and a 360 degree projection room provides an immersive underwater experience.

DreamPark XR Theme Park

DreamPark is in the Experiential Technology and Game On categories.

DreamPark is the first downloadable mixed-reality theme park platform, and overlays high-quality digital experiences onto real-world spaces using Meta Quest 3 headsets and mobile devices.

This proprietary system integrates spatial computing, real-time rendering, and intuitive UX to provide premium experiences that can be easily refreshed or changed completely. A single venue can host multiple IP overlays, switching from a fantasy quest to a racing game without reconstruction or downtime.

Families at Filoli

Filoli has submitted its family experiences into the Family category.

Filoli creates spaces where families can come together to discover, learn, and grow.

Family activities feature a scavenger hunt centred on the property's French bulldog Toto, and visitors can borrow Adventure Backpacks during their stay.

The Nature Playspace, Filoli’s Dress-Up Cart, and Platform Stage foster imaginative play, helping children engage with nature and express their creativity, and are accompanied by free art sessions, family-friendly theatre, and travelling exhibitions.

Funhouse at Pacific Park

Funhouse at Pacific Park has been entered into the Storytelling category by EPIC Entertainment Group.

Pacific Funhouse is a story-driven, multi-room attraction at Santa Monica Pier that brings Toonerville lore to life through seamless chapters and cinematic transitions.

With physical storytelling, invisible guidance, and seasonal evolution, this experience showcases how story architecture, scenic design, and technical choices reinforce one another to create an attraction that feels big, even on a compact footprint.

FuzionGamz and Attractions

FuzionGamz and Attractions is in the Experiential Technology and Game On categories.

FuzionGamz is an innovative live-action attraction that merges the immersive excitement of video games with the dynamic experiences of laser tag and escape rooms, powered by Unreal Engine and innovative infrared technology.

Guests come together in real life to play within a world built on floor-to-ceiling, dynamically interactive walls that react in real time to their movement choices and teamwork. Each round is different, and every player impacts how the adventure unfolds.

Ghost Boat (at Dells Boat Tours)

Moment Factory has submitted Ghost Boat (at Dells Boat Tours) in the Thrills category.

Moment Factory

Moment Factory

Described as 'pure nightmare fuel', this immersive event transforms the dramatic, natural setting of Cold Water Canyon into an intense after-dark experience where immersive multimedia storytelling, innovative scare kits, and a chilling narrative pull visitors into alternate realities.

Guests are introduced to the story during a 15-minute boat ride upriver, after which they embark on an immersive nighttime walk and encounter a creature at the canyon's edge.

Grease: The Immersive Movie Musical

Grease: The Immersive Movie Musical has been entered into the Brand Realisation and Immersive Experience categories by Secret Cinema.

Luke Dyson

Luke Dyson

In a world-first format, Grease: The Immersive Movie Musical presented a new approach to brand realisation through 360 degree musical immersion, broad audience accessibility, film, live, and more.

In an innovative approach, Secret Cinema was entrusted to create a new structure for the film, reimagining the IP and enabling spectacular live musical numbers, music and interaction to take place during pauses in the movie screening.

Immersive Horizon: Breathing Planet: Wind data, Jan 2020 – Feb 2020

Thermen & Badewelt Sinsheim (Thermengruppe Josef Wund) has entered this project in the Experiential Technology and Immersive Experience categories.

Thermen & Badewelt Sinsheim (Thermengruppe Josef Wund)

Thermen & Badewelt Sinsheim (Thermengruppe Josef Wund)

This 10-minute multisensory journey combines meditation, art, architecture, advanced technology, and atmospheric wind data from NASA to offer visitors a space to connect with their own breath and the planet's pulsation.

Developed by Thermengruppe Josef Wund in collaboration with the London-based artist collective Marshmallow Laser Feast and the design studio atelier522, the installation visualises the invisible rhythms of the Earth and the human body, turning data into an immersive, poetic encounter.

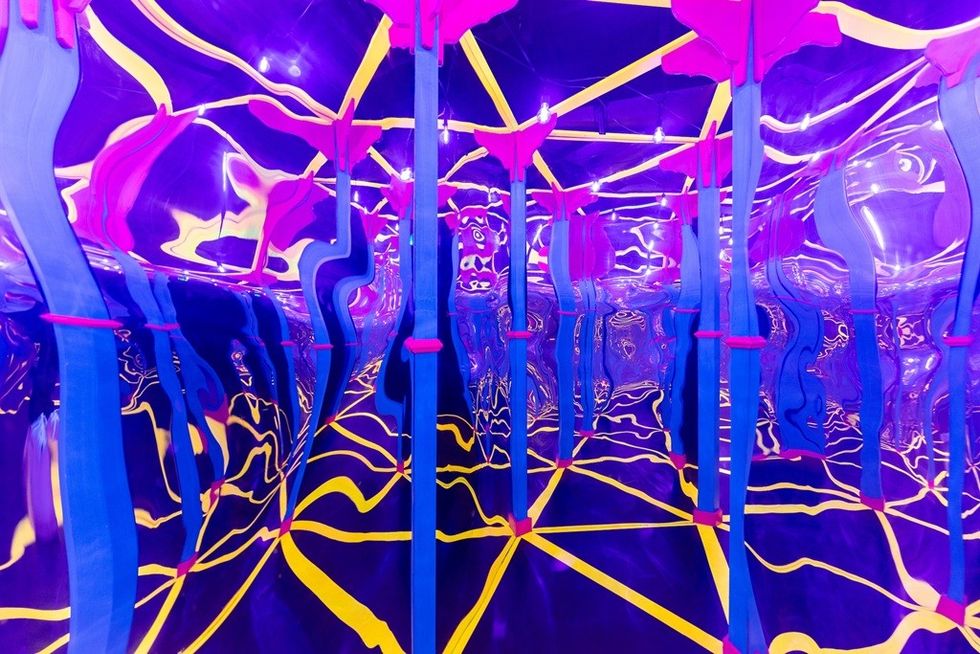

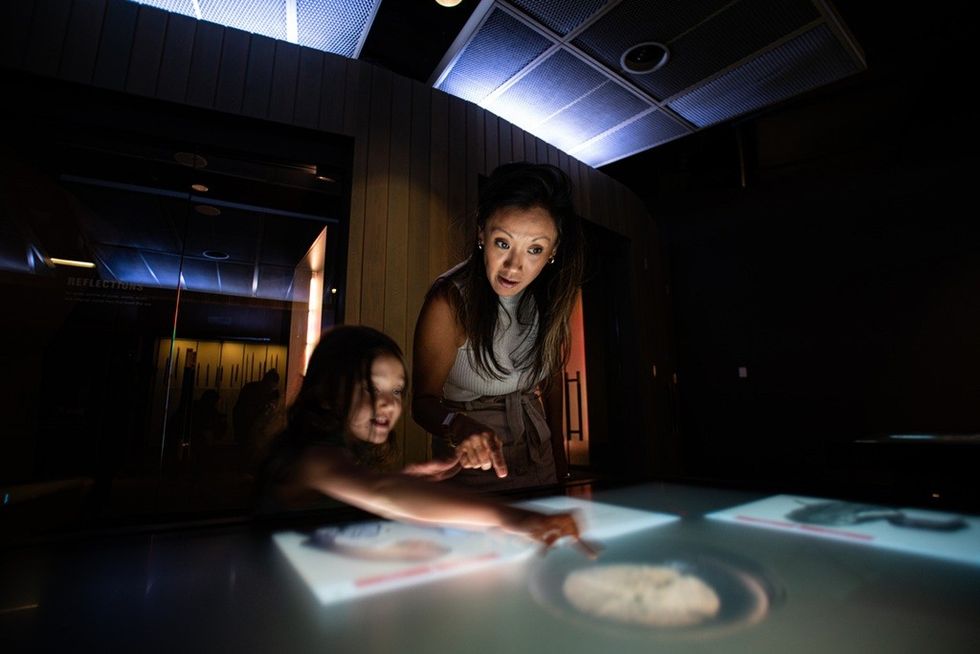

Immersive Imaginarium at Perot’s Children's Museum

The Immersive Imaginarium at Perot’s Children's Museum has been submitted to the Immersive Experience - Culture category by Kiss the Frog.

Immersive Imaginarium - Jungle World NorthernLight

Immersive Imaginarium - Jungle World NorthernLight

At the Perot Museum, the Imaginarium uses immersive technology and AI to spark creativity, transforming play into discovery as children interact with magical worlds that respond to their every move.

This bold new space, co-designed and developed by Kiss the Frog, features three larger-than-life playscapes that encourage exploration and discovery, with layered experiences for different age groups.

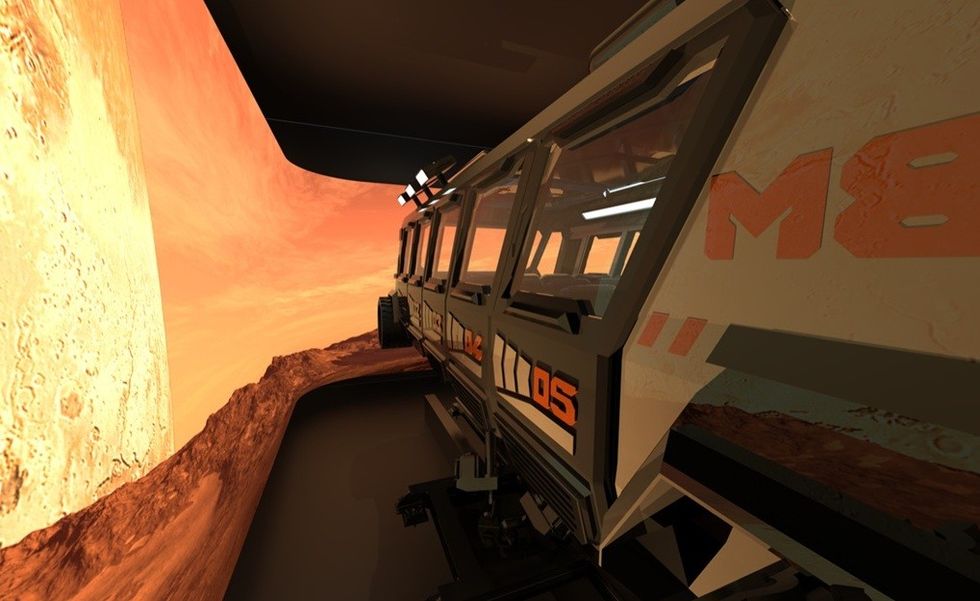

Immersive Tunnel – Mars Odyssey

DOF Robotics has entered Immersive Tunnel – Mars Odyssey in the Immersive Attractions category.

Immersive Tunnel – Mars Odyssey: A Journey Beyond Earth reimagines the immersive tunnel format to turn guests into active participants in a high-stakes space mission.

A 270 degree panoramic screen surrounds visitors in high-resolution visuals akin to leading sci-fi productions, and every sight, sound and movement is perfectly synchronised with DOF Robotics’ proprietary 6-DOF motion platform. This enables guests to feel every twist, turn, launch, and landing.

In Slavery's Wake: Making Black Freedom in the World

In Slavery's Wake: Making Black Freedom in the World has been entered in the Exhibit - Culture category by Ravenswood Studio, Inc.

National Museum of African American History & Culture

National Museum of African American History & Culture

A travelling exhibition from The National Museum of African American History and Culture, In Slavery’s Wake: Making Black Freedom in the World is the result of a 10-year collaboration between almost two dozen curators from ten institutions across four continents.

This partnership has resulted in an immersive, innovative experience that intertwines history, resistance, and contemporary reflection, connecting past injustices to present-day struggles for freedom.

InstaVR Arena

DIVR Labs's InstaVR Arena is in the Game On and Immersive Attractions categories.

InstaVR Arena is a groundbreaking, fully self-service, unattended free-roam VR attraction that enables entertainment venues to expand their offerings without increasing labour costs.

Immersive, wireless multiplayer gameplay is combined with an intuitive user onboarding system, and a compact footprint of 5 by 6 metres (16 by 20 feet). Additionally, the InstaVR Arena is plug-and-play and ready to operate in one day, reducing setup time to just hours.

Interstellar Arc

Felix & Paul Studios has submitted Interstellar Arc in the Immersive Experience and Storytelling categories.

Interstellar Arc combines wonder and science to explore humanity’s next leap beyond Earth, and marks the largest contiguous, high-fidelity, wireless VR environment to date.

Designed with cinematic scale and scientific grounding, the experience unfolds aboard a vast interstellar generational spaceship, complete with a rotating virtual centrifuge. A breakthrough in VR locomotion, this architectural form is impossible to construct at a human scale.

JAPI. Jalisco Paseo Interactivo

This project has been entered in the Exhibit - Culture category by Sietecolores.

Sietecolores. Ricardo Herrera

Sietecolores. Ricardo Herrera

Jalisco Paseo Interactivo (JAPI) was developed during a renovation of the Trompo Mágico Museum in Jalisco, Mexico, to mark the state's 200th anniversary. The interactive experience aims to celebrate Jalisco through the eyes of its inhabitants, and explores the reciprocal relationship between its people and its land.

Based on a vast, interconnected mosaic, each exhibit and interactive element has intrinsic value, but its whole meaning is revealed through its relationships with the other pieces.

John Wick Experience Las Vegas

John Wick Experience Las Vegas has been submitted into the Brand Realisation and Immersive Experience categories by Lionsgate.

™ & © 2025 Lions Gate Entertainment Inc. and related companies. All Rights Reserved.

™ & © 2025 Lions Gate Entertainment Inc. and related companies. All Rights Reserved.

The John Wick Experience at Area15 transports visitors into the world of the John Wick Las Vegas Continental, a meticulously constructed environment that upholds the blockbuster brand in a neon noir blend of decadence, storytelling, and action.

Drawing on elements from theme parks, stage shows, and escape rooms, this experience features more than a dozen highly themed rooms, interactive gameplay, character interactions, and challenges. Two luxurious bars serve themed cocktails, and a retail shop offers bespoke merchandise.

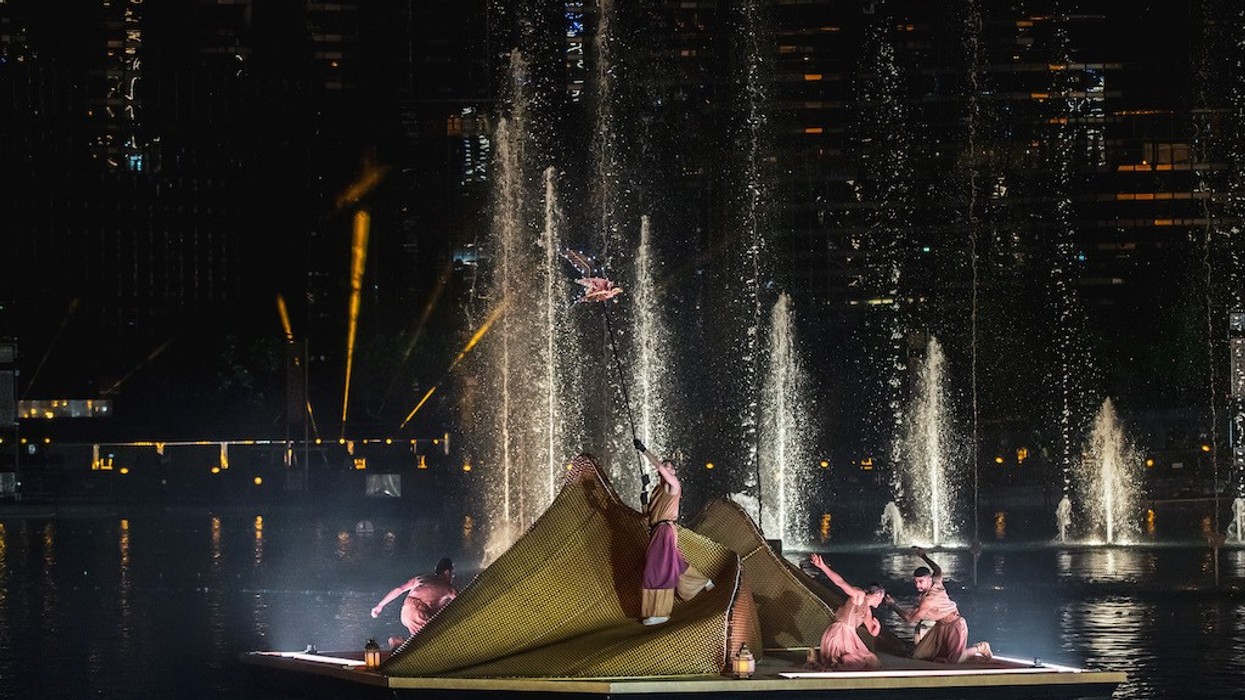

Justice League: Rise of the Penguin

Justice League: Rise of the Penguin has been entered into the Spectacular category by RWS Global & Parque Warner.

Justice League: The Rise of the Penguin at Parque Warner Madrid features much-loved DC characters in a 360 degree nighttime spectacular that takes place on and above the park’s central lake.

Jaw-dropping stunts, more than 300 synchronised drones, high-impact pyrotechnics, fireworks, flyboards, jet skis, and two iconic character vehicles tell the story, with real-time visuals, signage, and character identifiers displayed on a projection-mapped water curtain for audiences positioned around the lake.

Lucian Freud’s Etchings: A Creative Collaboration at Titanic Belfast

Lucian Freud’s Etchings: A Creative Collaboration at Titanic Belfast is in the Exhibit - Culture and Immersive Experience - Culture categories.

In collaboration with the V&A and others, Titanic Belfast transformed the exhibition of Freud’s etchings from static works into an entirely immersive cultural experience.

Whilst Freud's complex etchings can be challenging, this exhibition sought to make his work accessible and compelling. It combined fine art with immersive storytelling, multisensory technology and authentic recreation, centred on a 270-degree projection that animates his etching process.

Machu Picchu: Journey to the Lost City

Fever has entered Machu Picchu: Journey to the Lost City in the Immersive Experience - Culture and Marketing categories.

This VR experience transports audiences to 15th-century Machu Picchu, blending history, mythology, and emotion in a fully explorable, self-paced immersive journey through the heart of the Inca Empire.

Developed by Fever in partnership with Virtual Worlds, the project uses an ultra-detailed 3D scan of the iconic UNESCO World Heritage site, which was re-engineered to run on lightweight, untethered VR headsets, enabling free, intuitive exploration.

Media Matrexx high-tech urban core landmark showcasing kinetic media sculpture and transformative innovation

This project was submitted in the Creative Technology and Spectacular categories by Whimsy Day.

Media Matrexx is a year-round urban landmark where a kinetic figure appears every hour to deliver immersive stories. Digital performance is combined with a live stage that hosts artists, transforming the city centre into a cultural hub.

The sculpture is hidden inside the main building when not in use, and consists of 30 rings, each holding 50 independently controlled LED hexagons. At the start of each show, a custom hydraulic lift presents the sculpture in a sudden, theatrical transformation.

MGM Fantasy Box: redefining immersive venues through collaboration

MGM Fantasy Box: redefining immersive venues through collaboration has been entered in the Immersive Experience category by Disguise Systems.

The Fantasy Box at MGM Macau is an advanced venue powered by Disguise. With real-time content, reprogrammable environments, and adaptive technology, it sets a new benchmark for cultural spaces through creative versatility and precise control.

This multipurpose cultural venue spans 1,400 square metres and can be transformed into almost any environment. Encircled by a three-sided LED canvas rising seven metres high, it serves as a flexible stage for art exhibitions, concerts, brand activations, weddings, and corporate events.

Morning in the Garden: a podcast by Filoli

Filoli's Morning in the Garden is in the Storytelling category.

This podcast invites listeners on a walk through Filoli’s ever-changing landscape with director of interpretation, Willa Brock. Each 30- to 45-minute episode is structured as a sensory journey that combines soundscapes, storytelling, and diverse perspectives.

Filoli believes gardens are living storytellers that connect people to history, culture, and the natural world. Morning in the Garden extends this mission to digital platforms, turning seasonal changes, cultural traditions, and expert voices into an immersive audio experience that reaches audiences where they are.

MSC Cruises - MSC World Europa

MSC Cruises - MSC World Europa has been entered in the Experiential Technology and Spectacular categories by TAIT.

TAIT

TAIT

Six Swarovski crystal-clad chandeliers, including two designed for performer flight, have brought kinetic creativity to MSC World Europa, one of the world’s biggest cruise ships.

With automation, engineering, artistry, and over 20,000 crystals, TAIT has transformed a decorative element into a fully interactive performance platform that integrates light, motion, and human performers to create a unique dining experience.

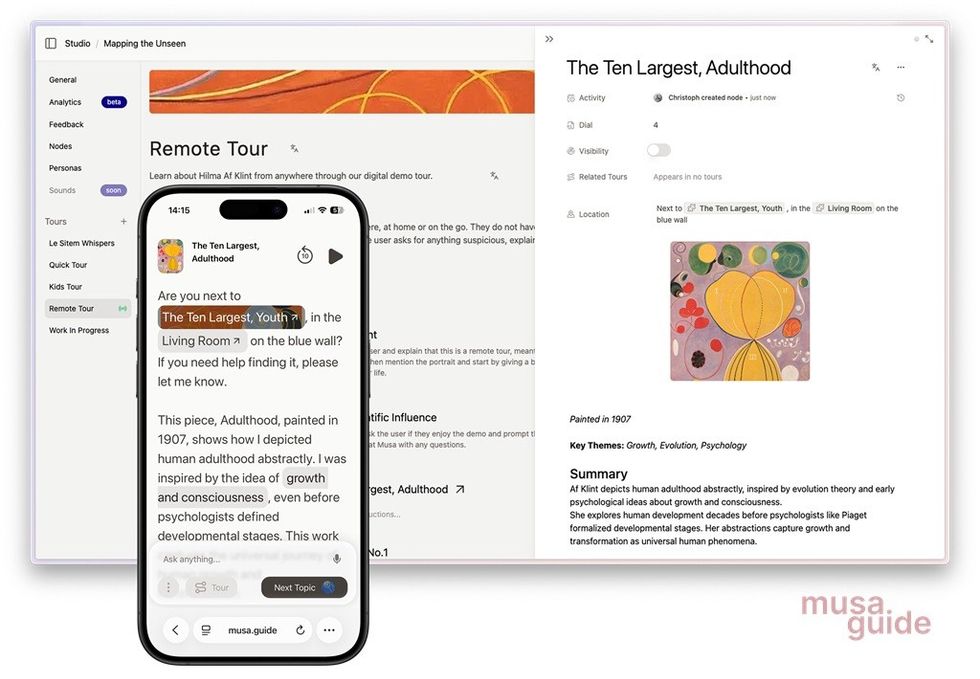

Musa AI tour guides

Musa Guide has entered this project in the Guest Journey category.

With Musa Guide, venues can create affordable AI audio tour guides that deliver personalised content in multiple languages.

An AI persona delivers the tour, using a context engine that draws on the venue’s verified materials, ensures provenance, and limits responses to approved sources. All visitors begin on a base path, such as a children's trail or an architecture focus, which becomes more tailored as they interact with the AI.

National WWI Museum and Memorial: Encounters exhibition

The Encounters exhibition at the National WWI Museum & Memorial has been submitted to the Experiential Technology and Storytelling - Culture categories by Electrosonic.

Encounters at the National WWI Museum & Memorial presents personal stories as 3D immersive experiences, drawing from authentic accounts from the Great War.

16 unique perspectives are told across four alcoves, and include a diverse range of voices such as combat soldiers, women munitions workers, colonial soldiers, a child, a dissenter, and others. In the Kemper Horizons Theater and the Battlescapes experience, visitors learn about trench warfare.

Niagara Takes Flight

Niagara Takes Flight has been submitted to the Immersive Experience - Culture category by Brogent Technologies Inc.

Niagara Takes Flight, Ontario’s first flying theatre, immerses visitors in Niagara’s heritage, landscapes, and history, combining culture and technology in a multi-sensory journey.

Set on synchronised gondola-style platforms before a massive 180 degree dome screen, the experience combines advanced motion simulation with wind, mist, and scent effects. Guests soar over Niagara’s landscapes, historic sites, and seasonal vistas, culminating in an up-close encounter with Horseshoe Falls.

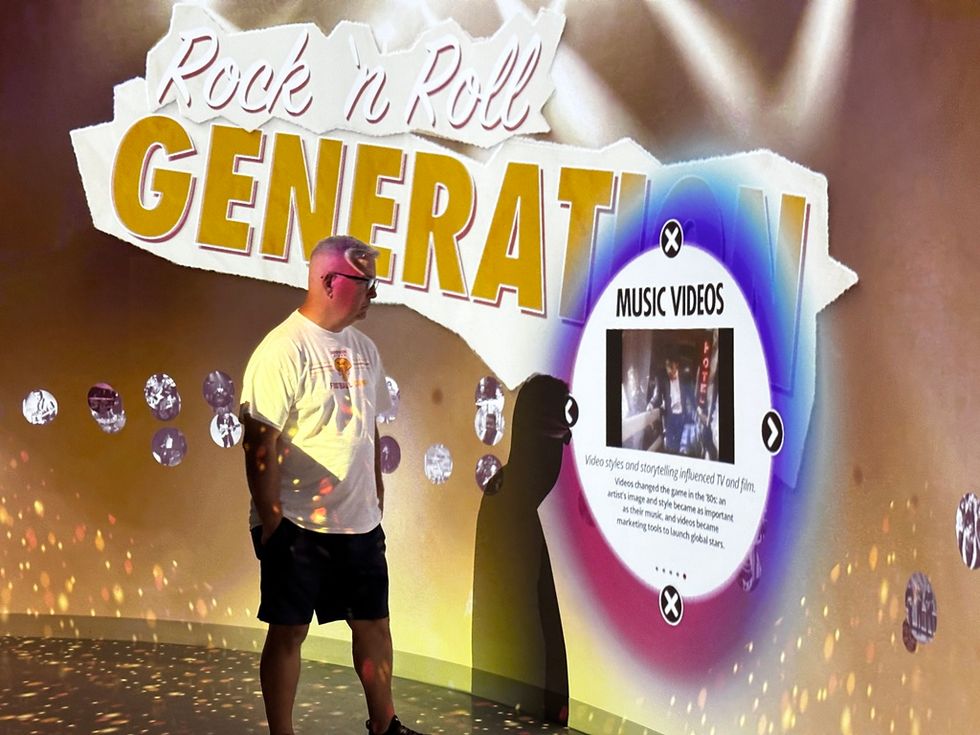

Not Fade Away at the Surf Ballroom Experience Center

Trivium Interactive, LLC has entered Not Fade Away at the Surf Ballroom Experience Center in the Immersive Experience - Culture and Storytelling - Culture categories.

Not Fade Away combines state-of-the-art technology with deep-dive storytelling to immerse visitors in the evolution of rock ‘n’ roll and the historic Surf Ballroom, where Buddy Holly, J.P. “The Big Bopper” Richardson and Ritchie Valens played their last show.

The experience begins with a film that interweaves the history of the Surf Ballroom, the tiny farming community of Clear Lake, and American music, presented through projections and surround-sound audio. Digital portals then explore a wide range of topics related to Surf and American music.

Odyssey Malta: where culture meets innovation

This project has been submitted to the Immersive Experience - Culture and Storytelling - Culture categories by Sarner International.

Odyssey Malta turns heritage into a storytelling journey, inviting visitors to explore 7,000 years of Malta’s history through immersive environments, compelling storytelling, and sensory design.

Malta’s first flying theatre serves as the centrepiece, offering a narrative-driven experience with dynamic motion, 8K visuals, projection mapping, and synchronised sensory effects that enable visitors to soar over the country's landscapes and historic sites, strengthening their emotional engagement with the story.

Of the Oak

Of the Oak has been submitted to the Creative Technology and Exhibit - Culture categories by Royal Botanic Gardens, Kew with Marshmallow Laser Feast.

Marshmallow Laser Feast, Of the Oak, 2025, courtesy of the artist

Marshmallow Laser Feast, Of the Oak, 2025, courtesy of the artist

Of the Oak is a six-metre immersive art installation at Kew Gardens. Using real-world data, it combines video, sound, meditations, and a digital field guide to reveal the hidden rhythms of the Lucombe oak and its role as a biodiversity hub.

A 12-minute immersive, interactive video installation, multichannel audio, and an online field guide invite guests on a sensory journey across the four seasons and beneath the bark, developed in collaboration with Kew’s expert scientists and horticulturists.

PerfectSwell Gen 6

PerfectSwell Gen 6 has been entered in the Experiential Technology and Splash categories by American Wave Machines, Inc.

The advanced PerfectSwell Gen 6 surf pool technology provides ocean-quality waves in diverse locations. This next-generation system introduces a compact, modular platform that delivers precise control over wave shape, timing, and intensity, enabling tailored sessions for all skill levels, from first-timers to elite surfers.

At its core is an array of high-efficiency pneumatic wave chambers, controlled by proprietary and patented adaptive software.

This enables a virtually unlimited range of wave types, including rights, lefts, peaks, barrels, and custom hybrids, to be generated on demand with precision, providing new possibilities for interactive storytelling and gamification.

porviva’s Magic Carpet: a simple solution for repairing surface damage and sealing floors

porviva - innovative surfaces' Magic Carpet is in the Blue Sky and Creative Technology categories.

For theme parks, wear and tear on floor surfaces can range from superficial paint flaking to deeper abrasions or cracks in the material. This is especially noticeable in immersive, elaborately themed areas, where a lengthy renovation would be detrimental.

porviva's Magic Carpet offers a way to repair surfaces for walkways in a short time, while maintaining a high level of theming.

It can also be used to add features such as anti-slip or cooling properties, and is suitable for conditions with high humidity, significant surface temperature fluctuations, and underwater use.

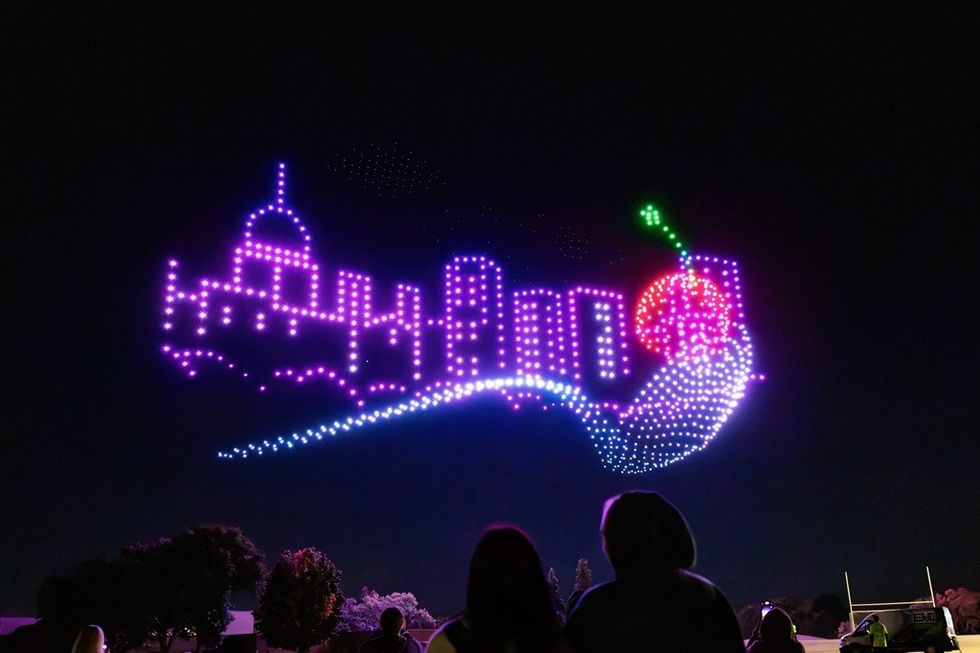

Postcard from Minnesota

Postcard from Minnesota has been entered into the Spectacular and Storytelling categories by Aerial Illuminations Drone Light Shows.

In a partnership with the City of Burnsville, this one-of-a-kind 1000-drone light show honours three first responders lost in Aerial Illuminations' hometown last year.

The fallen officers' badges and names are displayed in the sky, accompanied by imagery from across the state, including a theme park, ski hills, and the cityscape of Minneapolis, and a 500-ft-wide portrait of Prince, who was born and raised in the city.

RichCast by Panivox

RichCast has been submitted to the Experiential Technology and Storytelling - Culture categories by Panivox.

RichCast enables museums to offer interactive, game-like experiences that are affordable, engaging, and educational.

With this browser-based platform, organisations can create experiences that bring history, science, and culture to life with AI, video, animation, voice, images, quizzes, and interactives, all of which are delivered in multiple languages and are inclusive by design.

RPM Raceway's Kart Klash

RPM Raceway has entered Kart Klash in the Game On and Immersive Attractions categories.

Turning go-karting into a live-action video game, Kart Klash invites drivers to take on multi-level tracks featuring spirals, underpasses, drops, ramps, and tight turns that serve as layered battlegrounds for tactical manoeuvres and surprise attacks.

With top speeds of over 30 mph, the karts deliver torque and agility for both speed and friendly competition, fuelled by fun power-ups that are activated at trigger zones around the track.

San Diego Lego-Con at San Diego Comic-Con 2025

This project has been entered in the Brand Realisation and Marketing categories by XD Agency.

©XD Agency

©XD Agency

A Comic-Con within Comic-Con, San Diego Lego-Con blurred the line between exhibit and attraction, and between brand and fan. At the centre stood a 250-square-foot Lego build of the event, made from more than 200,000 bricks and 8,000 minifigures.

Hundreds of Easter eggs were hidden throughout, such as Marvel’s Doctor Doom reveal and even a tiny San Diego Lego-Con booth with its own micro-diorama. Attendees could design their own 10x10 Lego booths, with builds added to Lego-Con daily.

SCADstory Atlanta: reimagining the campus tour as immersive storytelling

BRC Imagination Arts has submitted SCADstory Atlanta: reimagining the campus tour as immersive storytelling in the Immersive Experience - Culture and Storytelling - Culture categories.

BRC Imagination Arts

BRC Imagination Arts

SCADstory Atlanta, developed for the Savannah College of Art and Design (SCAD), is the world's first 4D immersive brand story created by a university. It turns a typical campus visit into a theatrical experience where students, families, and visitors immerse themselves in the living story of creativity.

Storytelling and technology are integrated into a seamless emotional experience through projection mapping, real-time generative lighting, custom fragrances, and an original musical score. Highlights include a holographic illusion within a miniature set in a 'scene within a scene'.

SeaWorld San Diego – Jewels of the Sea: The Jellyfish Experience

SeaWorld San Diego's Jewels of the Sea: The Jellyfish Experience has been entered in the Exhibit - Animals and Immersive Experience categories by AVI-SPL.

SeaWorld San Diego’s Jewels of the Sea experience combines top-tier AV technology with live animal encounters, turning visuals, lighting, and sound into a memorable marine life experience.

The exhibit includes 18 aquariums, including 10 circular aquariums embedded in video walls, like portholes into the sea. Since jellyfish are not greatly affected by light or sound, the team was able to explore innovative AV effects, soundscapes, and smooth transitions. This created an engaging, sensory experience instead of a conventional exhibit.

Skyframe Piano

Sysco Productions has submitted Skyframe Piano in the Experiential Technology category.

Skyframe Piano is a world-first public installation that fuses live music with real-time generative media, and invites everyone to create their own skyscape, whether a casual passerby or concert-level pianist.

A street-level piano sits beneath the Skyframe LED ceiling, one of Europe’s largest suspended digital displays. Each note triggers a dynamic visual response overhead, such as sunlight, snowfall, or cherry blossoms. No two skies are the same, and the longer and more expressively a visitor plays, the more the sky transforms.

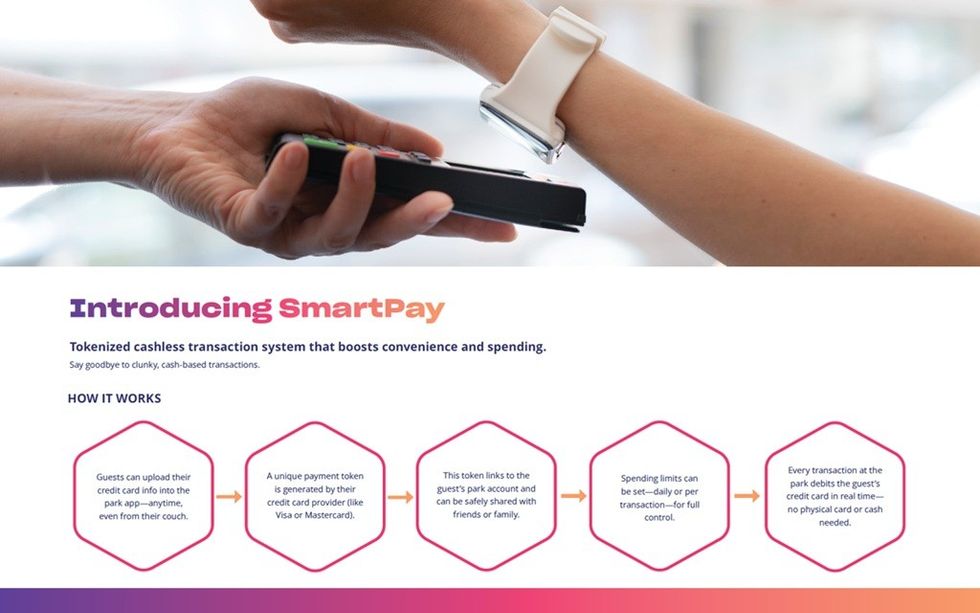

SmartPay: let guests focus on fun — not their wallets

SmartPay: let guests focus on fun — not their wallets has been submitted to the Experiential Technology and Guest Journey categories by Vantage Technology.

SmartPay by Vantage is a cashless, tokenised payment platform that enables in-venue transactions, app purchases, and real-time push offers. It redefines guest spending and engagement while generating additional revenue for operators.

By integrating payments with SmartPay, in-app purchasing with MyCart, and real-time engagement with SmartNotify, Vantage enables operators to deliver intuitive, personalised guest journeys, improve operational efficiency, and increase revenue.

SPIKE Add-ons: transforming roller coasters into interactive gaming platforms

Maurer Rides' SPIKE Add-ons: transforming roller coasters into interactive gaming platforms is in the Experiential Technology and Thrills categories.

Spike Add-Ons turn roller coaster rides into personalised, interactive adventures. Riders can control their speed, boosts, and gameplay features, enhancing excitement, competition, and replayability while elevating the coaster experience.

The suite of modular systems includes Starting Lights, Smoke Generator, Water Gate, Light Track, Co-Action, Magic Rings, Inversion Elements, Multiple Video Cams, and Interactive Themed Elements, all engineered to meet stringent safety standards.

SXSW London

TAIT has entered SXSW London in the Sustainability category.

TAIT

TAIT

As the inaugural European edition of the globally renowned festival, SXSW London redefined what a large-scale, citywide event could be when environmental impact is prioritised from the start.

A comprehensive environmental strategy was developed and deployed across three key phases: foundations, operational integration, and carbon management, with deliverables including policy development, staff training, carbon tracking, stakeholder alignment, and material reuse.

This framework was implemented at all 34 venues and involved over 150 suppliers, ensuring sustainability was integrated at every stage of planning and execution.

The Cortège: A Festive Funeral for Our Times

The Cortège's A Festive Funeral for Our Times is in the Spectacular and Storytelling categories.

The Cortège is an experiential theatre project that combines ancient rituals with contemporary spectacle. The outdoor experience takes place at dusk, and unfolds through music, dance, interactive robots, large-scale puppetry, and drone apparitions.

Inspired by Carl Jung’s theory of the collective unconscious, the performance draws on universal archetypes to tell a story felt more than understood. The Cortège evokes wonder by interweaving emotional catharsis, visual poetry, and technology in an experience that is at once ancient and futuristic.

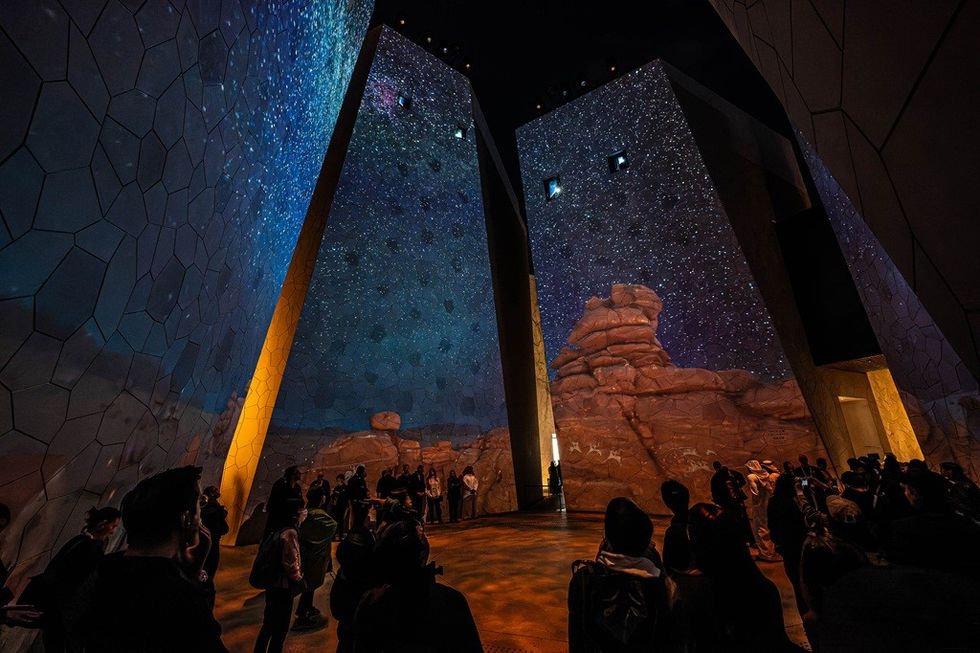

The Kingdom of Saudi Arabia Pavilion at Expo 2025

The Kingdom of Saudi Arabia Pavilion at Expo 2025 has been submitted to the Exhibit - Culture and Immersive Experience - Culture categories by BeWunder.

The Kingdom of Saudi Arabia Pavilion was the world's first temporary structure to attain WELL Health & Safety certification. This achievement in a wholly modular building set a new benchmark for Expo construction.

Inspired by traditional Saudi towns, it featured winding alleys and a central courtyard that invited visitors into the country's past, present, and future. Partnerships with Journey and Foster + Partners enhanced this story through digital storytelling, projection mapping, and spatial audio.

The Netherlands Pavilion at Expo 2025

BeWunder has submitted the Netherlands Pavilion at Expo 2025 in the Creative Technology category.

At Expo 2025 Osaka, the Netherlands Pavilion brought its theme, 'Common Ground,' to life through immersive media and creative technology.

A man-made sun served as the centrepiece, symbolising hope and clean energy. Custom-made interactive technologies allowed visitors to engage with digital content in real time, such as a bespoke interactive sphere system that turned guests' movements into personalised, dynamic responses.

The Philippines Pavilion at Expo 2025

BeWunder has also submitted the Philippines Pavilion at Expo 2025 to the Experiential Technology category.

Designed to honour Filipino biodiversity, craftsmanship, and community, the Philippines Pavilion at Expo 2025 Osaka combined sophisticated multimedia systems with artisanal craft in a journey that was both innovative and deeply human.

The pavilion’s exterior was made from more than 200 handwoven textiles created by local artisans from 18 regions across the Philippines. Inside, visitors could walk through a 'woven forest' of textiles and artworks, where traditional motifs were enhanced by dynamic lighting and interactive technologies.

The Secret Laboratory at Schloss Augustusburg

The Secret Laboratory at Schloss Augustusburg has been submitted to the Immersive Experience - Culture and Storytelling - Culture categories by CSB - Creative Studio Berlin GmbH.

THE ROOM Laboratories

THE ROOM Laboratories

The Secret Laboratory offers two entirely different, yet seamlessly integrated, historically rich edutainment experiences set in an authentic, historic location within the original castle.

Students decode herbal recipes with Anna of Saxony or analyse ore with Duke August in a combination of hands-on science, storytelling, and subtle technology, taught by an actor who brings the historical figures to life.

The Volcano Express

The Volcano Express is in the Storytelling and Thrills categories.

The Volcano Express takes audiences on an unforgettable, thrilling journey that reveals how volcanism lies at the heart of Iceland’s creation and survival.

The 9-minute immersive experience takes guests on a sweeping journey around the city, from hot springs to historic volcanic landscapes, and merges real eruption footage with visual effects to deliver an authentic and thrilling spectacle.

Visitors feel heat, wind, movement, and tremors, including specific temperature fluctuations and seismic activity.

Themed Masters Digital Platform - empowering the future of connectivity & collaboration

Themed Masters has entered its Digital Platform in the Blue Sky and Creative Technology categories.

Themed Masters streamlines how creative professionals collaborate, using over 1,900 industry-specific keywords to help professionals and speciality vendors showcase what sets them apart, and tools that provide a record of the partnerships that bring themed projects to life.

Studio creatives are notified when new gigs match their criteria. Vendors also receive tailored, qualified responses and can quickly identify the right fit.

THRIVE—The First People: Yesterday, Today, and Forever

THRIVE—The First People: Yesterday, Today, and Forever has been entered into the Exhibit - Culture and Storytelling - Culture categories by Arizona Museum of Natural History.

AZMNH

AZMNH

THRIVE , a co-authored exhibition with O’odham and Piipaash leaders, uses light, scent, sound and interactivity to inspire visitors to see the first peoples of Arizona not as a vanished past but as thriving cultures today.

Here, storytelling stands alongside science. Children engage with canals and desert agriculture, adults contemplate creation stories and the sacred river, and international visitors connect through sensory cues. An educational programme, including a live anthropology lab and a Speaker Series, accompanies the exhibition.

Top of the Rock

Top of the Rock has been submitted to the Experiential Technology and Immersive Experience categories by THG Creative.

THG Creative and TAIT

THG Creative and TAIT

Top of the Rock transforms an iconic building into a fully immersive journey, blending art, storytelling, and design with rides, media, and scenic elements to place guests within the living story of Rockefeller Center.

A gallery, pulsed media theatre, and immersive elevators are accompanied by rooftop experiences, The Beam, which recreates the famous 1932 'Lunch Atop a Skyscraper' photograph, and the soaring 360-degree Skylift viewing platform.

Transforming 3D attractions with Christie Sapphire 4K40-RGBH

Christie has entered this project into the Creative Technology category.

The first-of-its-kind hybrid RGB pure laser/laser phosphor projector, the Sapphire 4K40-RGBH delivers DCI-P3 colour, native 4K clarity, and an exclusive Infitec colour comb 3D option.

Developed to meet the needs of theme park operators replacing outdated lamp-based projectors in 3D attractions, the Sapphire 4K40-RGBH, with 40,950 lumens, is the world’s first high-brightness hybrid RGB pure-laser and laser-phosphor projector.

It is suitable for both 2D and 3D applications, front- and rear-projection, and any projection environment or screen type.

USA Pavilion at Expo 2025 Osaka

BRC Imagination Arts has submitted the USA Pavilion at Expo 2025 Osaka in the Immersive Experience and Storytelling categories.

Hufton + Crow

Hufton + Crow

The USA Pavilion embodied the strength of the American spirit and celebrated innovation and global cultural exchange.

Its two triangular buildings created a central plaza with a ‘floating’ translucent cube at its centre, surrounded by LED screens displaying images of American landmarks, landscapes, daily life, and exploration.

Inside, experiences showcased groundbreaking innovations in agriculture, nanotechnology, advanced materials, and aerospace technologies, and were accompanied by a full-service restaurant and a vibrant event programme.

Voyager Metabike

DOF Robotics has entered the Voyager Metabike in the Experiential Technology category.

Voyager Metabike is the world’s first interactive exercise simulation that combines immersive VR, adaptive resistance, and multiplayer competition to turn fitness into a personalised, gamified adventure.

Users can race friends or strangers worldwide, track live global rankings, and join tournaments. IoT-enabled, the platform offers cloud-based analytics and multiplayer connectivity, providing performance tracking, feedback, and seamless online interaction.

Registration now open for blooloop's Festival of Innovation

Registration now open for blooloop's Festival of Innovation

Join us at the Festival of Innovation to find out more and discover the winners of the 2025 blooloop Innovation Awards.

Register for free here.

Waco Surf

Waco Surf  Goldys trying the barrel waves at Lost Shore Surf Resort in ScotlandPhotographer: Samuel Howard

Goldys trying the barrel waves at Lost Shore Surf Resort in ScotlandPhotographer: Samuel Howard Goldys practising aerials on the fun waves at The Wave in Bristol, EnglandPhoto courtesy of The Wave

Goldys practising aerials on the fun waves at The Wave in Bristol, EnglandPhoto courtesy of The Wave Goldys enjoying warm water surfing at OANA Surf in SwitzerlandPhotographer: Alexis Feuille

Goldys enjoying warm water surfing at OANA Surf in SwitzerlandPhotographer: Alexis Feuille Waco Surf - The wave pool so nice, Goldys visited twicePhotographer: Rob Henson

Waco Surf - The wave pool so nice, Goldys visited twicePhotographer: Rob Henson Goldys trying the first surf park in Germany featuring Endless Surf technologyPhotographer: Tanner Wilson

Goldys trying the first surf park in Germany featuring Endless Surf technologyPhotographer: Tanner Wilson Goldys enjoying the 100-foot-wide Citywave at The LineUp at Wai KaiPhotographer: Pat Myers

Goldys enjoying the 100-foot-wide Citywave at The LineUp at Wai KaiPhotographer: Pat Myers Goldys enjoying a sunset session in the United States’ newest surf park, Atlantic ParkPhotographer: Andrew Tonra

Goldys enjoying a sunset session in the United States’ newest surf park, Atlantic ParkPhotographer: Andrew Tonra Surf Stadium is located 200 meters from the Shizunami Beach on the Pacific OceanPhotographer: Pedro Gomes

Surf Stadium is located 200 meters from the Shizunami Beach on the Pacific OceanPhotographer: Pedro Gomes This one-of-a-kind surf park was retrofitted into a Rotterdam canal in the NetherlandsPhotographer: Adriënne Wildeman

This one-of-a-kind surf park was retrofitted into a Rotterdam canal in the NetherlandsPhotographer: Adriënne Wildeman

Park of Poland

Park of Poland

Augmented Games, Moment Factory

Augmented Games, Moment Factory

eCom Calendar

eCom Calendar

Moment Factory

Moment Factory Luke Dyson

Luke Dyson Thermen & Badewelt Sinsheim (Thermengruppe Josef Wund)

Thermen & Badewelt Sinsheim (Thermengruppe Josef Wund) Immersive Imaginarium - Jungle World NorthernLight

Immersive Imaginarium - Jungle World NorthernLight

National Museum of African American History & Culture

National Museum of African American History & Culture

Sietecolores. Ricardo Herrera

Sietecolores. Ricardo Herrera ™ & © 2025 Lions Gate Entertainment Inc. and related companies. All Rights Reserved.

™ & © 2025 Lions Gate Entertainment Inc. and related companies. All Rights Reserved.

TAIT

TAIT

Marshmallow Laser Feast, Of the Oak, 2025, courtesy of the artist

Marshmallow Laser Feast, Of the Oak, 2025, courtesy of the artist

©XD Agency

©XD Agency BRC Imagination Arts

BRC Imagination Arts

TAIT

TAIT

THE ROOM Laboratories

THE ROOM Laboratories

AZMNH

AZMNH THG Creative and TAIT

THG Creative and TAIT

Hufton + Crow

Hufton + Crow

Registration now open for blooloop's Festival of Innovation

Registration now open for blooloop's Festival of Innovation